VANCOUVER, British Columbia, May 17, 2022 (GLOBE NEWSWIRE) -- LMI Technologies (LMI), a leading developer of 3D scanning and inspection solutions, is pleased to announce the official release of its new Gocator® 5500 series of smart 3D line confocal sensors. This major product release introduces the first line confocal sensor running Gocator®'s trusted smart sensor platform, complete with next-generation on-sensor IIoT vision web-based software, onboard measurement tools, I/O connectivity, and much more.

Gocator® 5500 sensors are unique among existing confocal technologies in that they feature a dual-axis design that delivers simultaneous generation of 3D topography, 3D tomography, and 2D intensity data. This allows Gocator® 5000 sensors to scan practically any material type--including multi-layered, transparent/translucent, curved edge, shiny, textured, mixed, and many more--with submicron precision and at a level of quality and speed that outperforms competing confocal technologies.

A quick look at Gocator 5500 sensor capabilities:

- Simultaneous generation of multiple profiles from multi-layer structures.

- Generates 1792 data points per profile.

- Fast scan rates (Over 10 kHz with PC acceleration).

- High X resolution, sub-micron Z precision.

- Handles a wide variety of material types.

- Dual-axis optical design provides higher signal quality.

- Runs next-generation onboard measurement and inspection software.

"The Gocator® 5500 Series introduces a powerful line confocal scanning approach for the inspection of challenging material structures such as multi-layer, transparent and curved edge, and now with next-generation on-sensor IIoT vision software and Gocator's renowned smart features and capabilities. The result is an end-to-end, user-friendly surface evaluation solution that provides customers with unmatched performance, leveraging the industry's first smart LCI technology", said Mark Radford, CEO, LMI Technologies.

Gocator® 5504 and 5512 models are now available for order at orders@lmi3d.com. The Gocator 5516 model will be available for order later in 2022. You can also email contact@lmi3d.com to discuss the right Gocator 5500 model for your application.

If you'd prefer to learn more details about this exciting new product before getting in touch, visit our Gocator 5500 product page.

About LMI Technologies

As the global leader in 3D scanning and inspection, LMI Technologies works to advance quality and productivity with 3D sensor technology. Our award-winning, FactorySmart® laser, snapshot, and line confocal sensors improve the quality and efficiency of factory production by providing fast, accurate, reliable inspection solutions that leverage smart 3D technologies. Unlike contact-based measurement or 2D vision, our non-contact solutions add 3D shape information that is critical to achieving 100% quality control.

To learn more about how LMI's inspection solutions can benefit your business, we invite you to contact us at contact@lmi3d.com or visit us at www.lmi3d.com to explore the possibilities of smart 3D technology.

Media Contact:

Theresa Ng

Marketing Coordinator

LMI Technologies

Tel.: +1 604 636 1011

E-mail: theresa.ng@lmitechnologies.com

Related Images

Image 1: Introducing Gocator 5500 Series

Gocator 5500 sensors introduce the power of line confocal imaging to the world's leading smart sensor platform for inspection of a wide range of challenging material structures.

Image 2: Gocator 5500 for Multi-Layered Cell Phone Glass Inspection

Gocator® 5500 sensors simultaneously generate 3D tomography, 3D topography, and 2D intensity data for each layer of a material, making it possible to measure the thickness of individual layers or detect defects on secondary layers.

Image 3: Gocator 5500 for Semiconductor Inspection

Gocator 5500 sensors are used in various stages of semiconductor manufacturing, including wafer dimensioning, sorting, and defect detection.

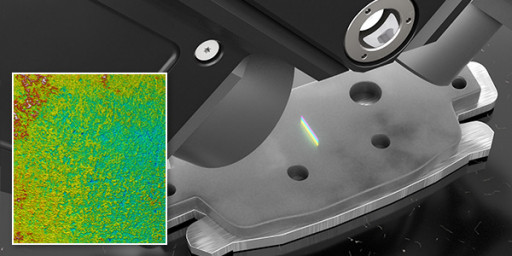

Image 4: Gocator 5500 for Automotive Component Inspection

Gocator 5500 sensors provide high resolution, wide scan coverage inspection of a range of automotive components, such as brakepad surface roughness measurement.

This content was issued through the press release distribution service at Newswire.com.

Attachment