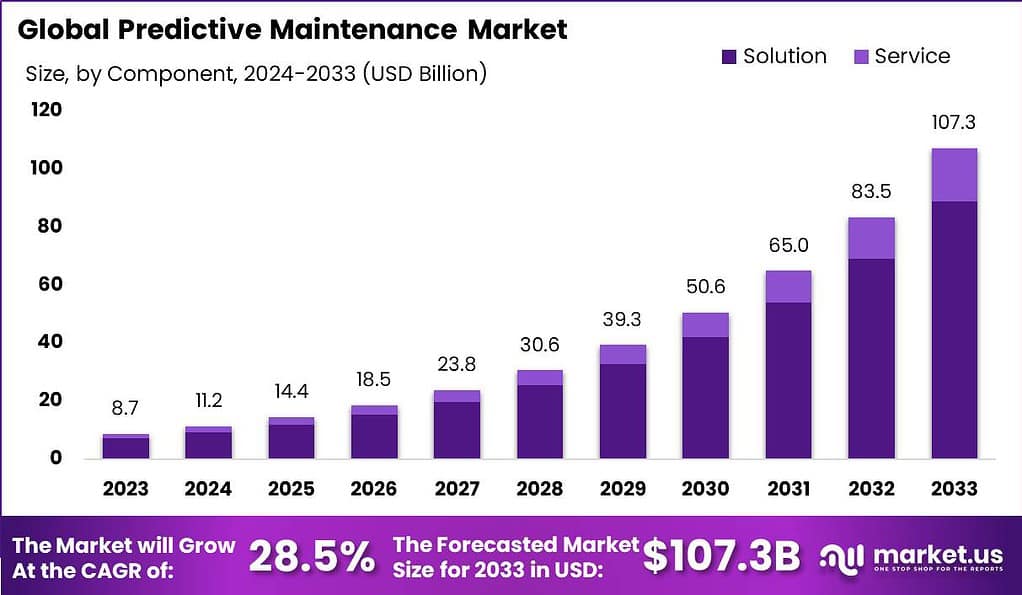

New York, Dec. 11, 2023 (GLOBE NEWSWIRE) -- According to Market.us, In 2023, the gross revenue of the global predictive maintenance market is estimated to reach USD 8.7 Billion. A comprehensive analysis suggests that investments in the predictive maintenance sector could experience an annual growth rate of 28.5% from 2024 to 2033. The analysis further delves into the key determinants driving market growth, projecting a market valuation of USD 107.3 Billion by 2033.

Predictive maintenance is an advanced approach of maintenance that utilizes data analytics, machine learning, and sensor technologies to anticipate potential failures of equipment and enhance maintenance. By analyzing and collecting real-time information from machinery and other equipment, predictive maintenance is able to identify patterns, detect abnormalities, and give an early warning of upcoming breakdowns.

The market for predictive maintenance encompasses the development, implementation, and adoption of predictive maintenance solutions and services. It is driven by rising demands for cost-effective maintenance strategies, increased asset reliability and optimized maintenance schedules across industries. Utilizing predictive analytics and machine learning algorithms, organizations can streamline their maintenance processes, decrease the amount of unnecessary downtime, and increase the life that their machines.

Want to Access the Statistical Data and Graphs, Request PDF Sample @ https://market.us/report/predictive-maintenance-market/request-sample/

“Predictive maintenance is not just a trend, it’s a revolution. It’s the future of how we will maintain our equipment, optimizing efficiency and profitability across every industry.” Says Mr. Yogesh Shinde Team Lead @ Market.us.

Key Takeaways

- Market Growth Projection: The market is expected to reach a valuation of USD 107.3 billion by 2033, experiencing an impressive CAGR of 28.5%, showcasing its substantial growth potential.

- Component Analysis: In 2023, the Solution segment dominated the market with over 83% share. Integrated solutions seamlessly blend predictive features into existing systems, while standalone solutions offer dedicated platforms.

- Deployment Models: On-premise solutions accounted for 71% of the market due to data security concerns. Cloud-based solutions, though smaller, provide scalability and flexibility benefits.

- Enterprise Size Impact: Large Enterprises held a dominant position with over 75% market share in 2023, investing in advanced technologies. SMEs, steadily adopting predictive maintenance, represented a growing market segment.

- Monitoring Techniques: Vibration Monitoring led with over 28% market share, crucial in detecting abnormalities in rotating machinery. Torque Monitoring, while smaller, is relevant in torque-sensitive processes.

- End-Use Industries: Manufacturing led with over 29% share in 2023. Other key sectors include Automotive & Transportation, Aerospace & Defense, Energy & Utilities, Healthcare, IT & Telecommunications, and Oil & Gas.

- Key Market Trends: Edge computing's importance rises, prescriptive maintenance emerges, and hybrid models combining different maintenance strategies become prevalent.

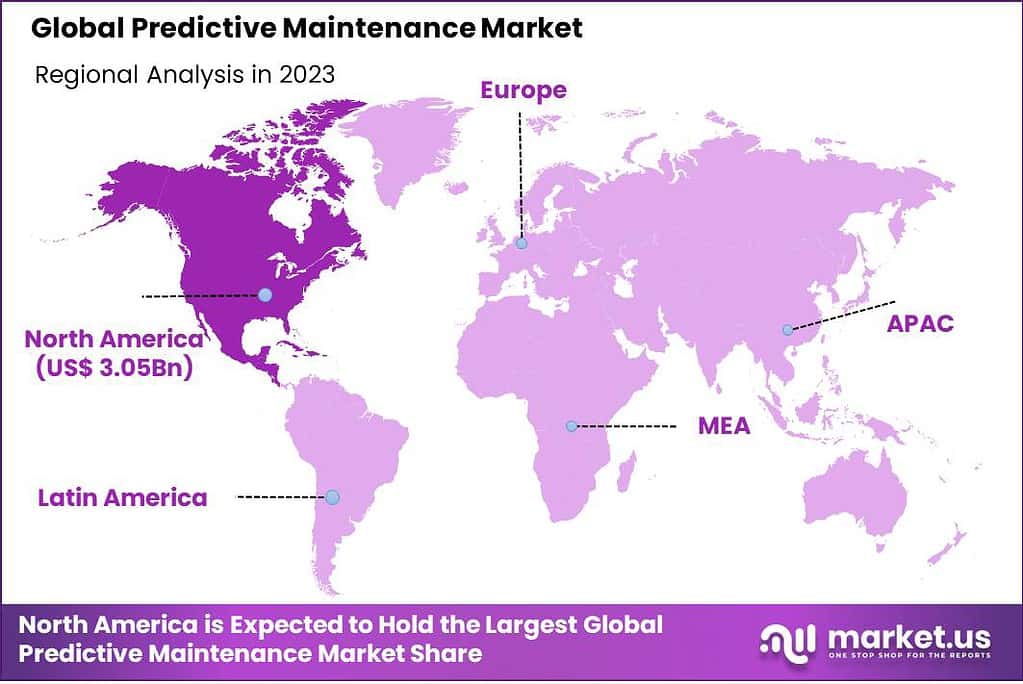

- Regional Analysis: North America dominated in 2023, seizing over 35% share, driven by cost-saving potential and operational efficiency. Europe and APAC made significant strides, focusing on sustainability and industrial growth.

- Key Players Analysis: Market leaders include IBM Corporation, General Electric (GE), SAP SE, Microsoft Corporation, PTC Inc., Schneider Electric SE, Siemens AG, Honeywell International Inc., ABB Ltd., Bosch.IO, Rockwell Automation Inc., and Uptake Technologies Inc.

Top Trends in the Global Predictive Maintenance Market

- Edge Computing's Ascendancy: Edge computing, a paradigm that processes data closer to its source rather than in a centralized data center, gains prominence. By analyzing data locally, at the edge where sensors are situated, real-time analysis becomes feasible. This approach allows for quicker responses to anomalies, a crucial aspect in predictive maintenance for swift action to prevent potential failures.

- Emergence of Prescriptive Maintenance: The evolution from predictive to prescriptive maintenance marks a significant shift. Prescriptive maintenance not only predicts impending failures but also offers actionable recommendations for maintenance actions. This proactive approach optimizes decision-making, streamlining maintenance tasks and enhancing overall operational efficiency.

- Hybrid Maintenance Models: A growing trend involves combining predictive maintenance with preventive and corrective strategies. Hybrid maintenance models offer flexibility and cost-effectiveness. By integrating different maintenance approaches, organizations optimize asset lifespans, reduce downtime, and curtail operational costs effectively.

- Rise of Remote Monitoring: Remote monitoring, facilitated by IoT sensors and connected devices, gains traction. It allows maintenance teams to monitor assets from any location, improving efficiency and curbing travel costs. This trend aligns with the growing demand for remote operations and maintenance solutions, ensuring uninterrupted asset monitoring and management.

Build a Future-proof Business! Buy our Premium Insights at Affordable Prices Now: https://market.us/purchase-report/?report_id=110488

Regional Analysis

In 2023, North America held a dominant market position, capturing more than a 35% share in the predictive maintenance landscape. This region's supremacy can be attributed to the robust adoption of advanced technologies across industries, particularly in the United States and Canada, along with substantial investments in R&D activities. The demand for Predictive Maintenance in North America was valued at USD 3.05 billion in 2023.

The market is propelled by the presence of key players offering cutting-edge predictive maintenance solutions and the widespread implementation across various sectors such as manufacturing, automotive, and aerospace. Moreover, the focus on enhancing operational efficiency, reducing downtime, and optimizing asset performance has significantly contributed to the growth of predictive maintenance solutions in this region.

Competitive Landscape

The competitive landscape of the market has also been examined in this report. Some of the major players include:

Top 12 Biggest Key Players

- IBM Corporation

- General Electric (GE)

- SAP SE

- Microsoft Corporation

- PTC Inc.

- Schneider Electric SE

- Siemens AG

- Honeywell International Inc.

- ABB Ltd.

- Bosch.IO

- Rockwell Automation Inc.

- Uptake Technologies Inc.

Scope of the Report

| Report Attributes | Details |

| Market Value (2023) | US$ 8.7 Billion |

| Forecast Revenue 2033 | US$ 107.3 Billion |

| CAGR (2023 to 2033) | 28.5% |

| North America Revenue Share | 35% |

| Base Year | 2022 |

| Historic Period | 2017 to 2022 |

| Forecast Year | 2023 to 2033 |

Market Drivers

The driving factors of the predictive maintenance market are multifaceted. Technological advancements stand out as a primary driver, with the evolution of IoT, AI, and machine learning enabling more accurate predictive algorithms. Cost savings through reduced downtime and optimized maintenance schedules represent another crucial factor enticing industries to adopt these solutions. Additionally, the growing trend toward predictive analytics for efficient asset management, the increasing need to prevent unexpected breakdowns, and the shift from reactive to proactive maintenance strategies further fuel the market's growth.

Market Restraints

Conversely, several restraining factors challenge the widespread adoption of predictive maintenance. Chief among these is the high initial investment required for implementing predictive maintenance systems, including the costs associated with hardware, software, and skilled personnel. Data security concerns and the need for robust infrastructure also hinder adoption. Moreover, the complexity of integrating these systems into existing operations and the reluctance of some industries to shift from traditional maintenance approaches pose significant restraints to market expansion.

Market Opportunities

Amidst these dynamics lie growth opportunities for the predictive maintenance market. The rising demand for cloud-based predictive maintenance solutions presents a substantial opportunity, offering scalability, flexibility, and cost-effectiveness. Furthermore, the increasing adoption of predictive maintenance by small and medium-sized enterprises (SMEs) seeking tailored, affordable solutions creates a new market segment. The emergence of innovative technologies like edge computing and predictive analytics in edge devices also opens doors for market growth by facilitating real-time data analysis.

Market Challenges

However, challenges persist in this landscape. One notable challenge is the scarcity of skilled professionals proficient in handling predictive maintenance systems and interpreting complex data analytics. The need for continuous training and upskilling in this field remains a hurdle. Additionally, interoperability issues between various systems and the integration of predictive maintenance with legacy equipment pose technical challenges. Moreover, ensuring the accuracy and reliability of predictive algorithms and handling vast amounts of data effectively are ongoing challenges for market players.

Market Trends

A key market trend shaping the predictive maintenance landscape is the convergence of predictive maintenance with other technologies like digital twins and augmented reality. The integration of these technologies allows for enhanced predictive capabilities and facilitates remote monitoring and troubleshooting, revolutionizing maintenance practices. Moreover, the move towards predictive maintenance-as-a-service (PdMaaS) models and the increasing use of predictive analytics in supply chain management represent significant trends, indicating the market's evolution towards more comprehensive and accessible solutions.

Stay informed about market trends and growth opportunities: https://market.us/report/predictive-maintenance-market/request-sample/

Report Segmentation of the Predictive Maintenance Market

Component Outlook:

- Solution Segment Dominance: In 2023, the Solution segment held a significant market share, around 83%. This segment encompasses integrated and standalone solutions, offering predictive maintenance capabilities. Integrated solutions seamlessly integrate predictive maintenance features into existing systems, optimizing asset performance. Standalone solutions, on the other hand, cater to specific business needs, highlighting the market's recognition of tailored solutions.

- Criticality of Service Segment: While smaller in market share, the Service segment is pivotal. It covers integration, support, maintenance, and training services. Integration services assist in seamless implementation, while support and maintenance ensure continuous functionality. Training and consulting are essential for skill development, reflecting the service segment's importance despite its lower share.

Deployment Model:

- On-Premise Dominance: On-premise solutions accounted for over 71% of the market share in 2023. Organizations prefer this model due to data security concerns and the need for data control. Industries with sensitive data rely on this model, reflecting a demand for in-house infrastructure.

- Cloud-Based Flexibility: Although smaller in share, the Cloud segment offers scalability and accessibility benefits. Organizations opt for this model for its flexibility and cost-efficiency. Cloud-based solutions facilitate remote access and real-time data analysis, appealing to businesses aiming for agility.

Enterprise Size:

- Large Enterprise Adoption: Large enterprises dominated the market, holding over 75% of the share. They invest in advanced predictive maintenance technologies, leveraging AI-driven analytics and IoT sensors. Their substantial market share reflects the sector's recognition of predictive maintenance's advantages in optimizing operational efficiency.

- SMEs' Steady Growth: SMEs, while holding a smaller market share, are steadily adopting predictive maintenance. Providers offer scaled-down solutions catering to their specific needs, making predictive maintenance accessible to smaller businesses. This segment's growing share highlights SMEs' awareness of the benefits of predictive maintenance in preventing failures.

Monitoring Technique:

- Vibration Monitoring Prevalence: Vibration Monitoring led in 2023, capturing over 28% of the market. It plays a critical role in detecting abnormalities in rotating machinery. Industries, particularly manufacturing and heavy machinery, prioritize this technique due to its significance in identifying equipment health issues.

- Torque Monitoring Relevance: While smaller in share, Torque Monitoring is crucial in industries sensitive to torque-related processes. It aids in predicting maintenance needs by identifying deviations in torque levels, influencing sectors like automotive and aerospace.

End-Use:

- Manufacturing's Leadership: Manufacturing emerged as the dominant sector with a share exceeding 29% in 2023. Predictive maintenance empowers manufacturers to proactively address potential equipment failures, optimizing operations and reducing downtime.

- Automotive & Transportation's Significance: In an industry valuing safety and reliability, predictive maintenance is invaluable. Automotive and transportation sectors utilize these solutions to minimize breakdowns, optimize fleet performance, and enhance passenger safety.

Market Segments

Component

- Solution

- Integrated

- Standalone

- Service

- Integration and Deployment

- Support & Maintenance

- Training & Consulting

Deployment Model

- Cloud

- On-premise

Enterprise Size

- Small & Medium Enterprises

- Large Enterprises

Monitoring Technique

- Torque Monitoring

- Vibration Monitoring

- Oil Analysis

- Thermography

- Corrosion Monitoring

- Others

End-Use

- Aerospace & Defense

- Automotive & Transportation

- Energy & Utilities

- Healthcare

- IT & Telecommunications

- Manufacturing

- Oil & Gas

- Others

By Geography

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherland

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Recent Developments

- November 2023, Smart Eye unveiled a novel remote predictive maintenance system seamlessly incorporated with its eye-tracking technology.

- October 2023, IBM and Baker Hughes disclosed a collaborative effort to formulate and deliver predictive maintenance solutions tailored for the oil and gas industry.

- September 2023, ABB and SKF initiated a joint venture aimed at delivering predictive maintenance services dedicated to industrial equipment.

Trending Technology Related Reports

- Predictive Analytics Market size to reach USD 9.5 Bn In 2022 and is Projected To Reach a Revised Size Of USD 61.9 Bn By 2032

- Automotive Predictive Maintenance Market size is expected to be worth around USD 100 Billion by 2032, growing at a CAGR of 18.6%.

- Cloud Gaming Market size is expected to be worth around USD 143.4 Billion by 2032 from USD 3.4 Billion in 2022, growing at a CAGR of 46.9%.

- Blockchain Technology Market size is projected to surpass at USD 12,895 Bn by 2032 and it is growing at a CAGR of 68% from 2022 and 2032.

- Industry 4.0 market size is expected to be worth around USD 482 billion by 2032 from USD 93 billion in 2023; CAGR of 20.7%

- Semiconductor Market is estimated to garner a market size of USD 1,307.7 Billion by 2032; rising at a CAGR of 8.8% from 2023 to 2032.

- Customer Care BPO Market Poised to Attain USD 43,096.6 Million by 2032 From USD 25,459.3 Million with Growing CAGR of 6.2%.

FAQS on Predictive Maintenance Market

1. What is predictive maintenance?

Predictive maintenance is a proactive approach to maintenance that uses data analytics, machine learning, and sensors to predict when equipment is likely to fail so that maintenance can be performed just in time.

2. What are the key benefits of implementing predictive maintenance?

Benefits include increased equipment uptime, reduced maintenance costs, improved safety, and the ability to plan and schedule maintenance activities more efficiently.

3. How big is Predictive Maintenance Market?

The Global Predictive Maintenance Market size was projected to be USD 8.7 billion in 2023, and by the end of 2024, it is expected to reach a valuation of USD 11.2 billion. During the forecast period, the global Predictive Maintenance market is forecasted to exhibit a 28.5% Compound Annual Growth Rate (CAGR), reaching a substantial size of USD 107.3 billion by 2033.

4. What role does the Internet of Things (IoT) play in predictive maintenance?

The IoT plays a crucial role by connecting sensors and devices to a network, allowing real-time data collection. This data is then used for predictive analytics to anticipate equipment failures.

About Us

Market.US (Powered by Prudour Pvt Ltd) specializes in in-depth market research and analysis and has been proving its mettle as a consulting and customized market research company, apart from being a much sought-after syndicated market research report-providing firm. Market.US provides customization to suit any specific or unique requirement and tailor-makes reports as per request. We go beyond boundaries to take analytics, analysis, study, and outlook to newer heights and broader horizons.

Follow Us On LinkedIn Facebook Twitter

Our Blog: