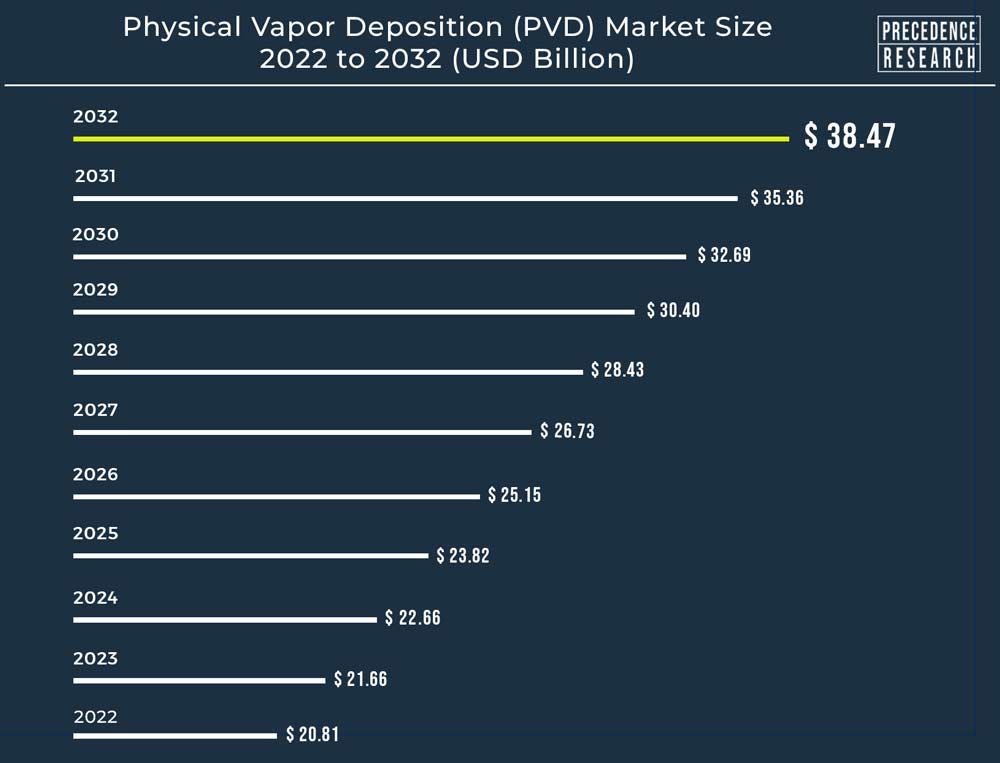

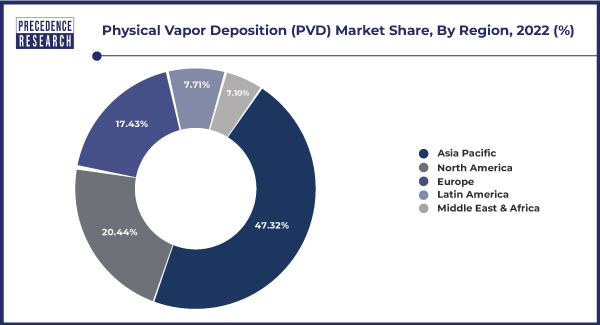

Ottawa, Jan. 11, 2024 (GLOBE NEWSWIRE) -- The global physical vapor deposition (PVD) market size accounted for USD 22.66 billion in 2024 and is expected to reach around USD 32.69 billion by 2030, According to Precedence Research. Asia Pacific led the global market with the largest market share of 47.32% in 2022.

The Physical Vapor Deposition (PVD) market is driven by the growing demand for electronics & semiconductors, rising adoption in medical applications, automotive industry growth, advancements in coating technologies, focus on energy efficiency and others.

Physical Vapor Deposition (PVD) is a thin film deposition technique used in various industries, including semiconductor manufacturing, optics, aerospace, and decorative coatings. PVD is a type of vacuum deposition method where a material undergoes a physical transformation from a solid to a vapor phase and then condenses onto a substrate to form a thin film. PVD offers several advantages, including the ability to deposit films with high purity, precise control over film thickness, and the ability to coat complex shapes and substrates.

Common PVD techniques include thermal evaporation, electron beam evaporation, and various forms of sputtering, such as magnetron sputtering and ion beam sputtering. Applications of PVD span a wide range, from creating protective coatings on cutting tools to depositing reflective layers on mirrors and manufacturing electronic devices with thin film components. PVD is a versatile technology that plays a crucial role in the development of advanced materials and devices in various industries.

Download the Sample Pages@ https://www.precedenceresearch.com/sample/2285

Key Insights:

- The Asia Pacific region is expected to witness a CAGR of 7.3% from 2023 to 2032.

- The PVD equipment application segment is growing at a CAGR of 6.3% from 2023 to 2032.

- The services segment is growing at a CAGR of 7.7% from 2023 to 2032.

- The electronics segment will reach a CAGR of 7% from 2023 to 2032.

Regional Stance:

Asia Pacific is expected to hold a substantial market share over the forecast period. The region of Asia-Pacific was determined to be the largest market for PVD coating consumption because of rising demand from nations like China, India, and Japan. One of the biggest markets for domestic air travel as well as one of the biggest producers of aircraft is China. Furthermore, the nation's industry for producing aviation parts and assemblies has been expanding quickly, with more than 200 small makers of these components using and demanding physical vapor deposition (PVD) coating.

- The Boeing Commercial Outlook 2021–2040 projects that by 2040, 8,700 new deliveries with a market service value of USD 1,800 billion will be produced in China. Furthermore, at a total estimated cost of USD 1.2 trillion, Chinese airline businesses want to buy 7,690 new aircraft over the next 20 years, which is projected to drive up demand for PVD coatings.

PVD coatings are the perfect functional metal coating for the aerospace sector since they are durable and have low friction. Thus, the aforementioned stats drive the market expansion during the forecast period.

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

Physical Vapor Deposition (PVD) Market Scope

| Report Coverage | Details | |

| Growth Rate from 2023 to 2032 | CAGR of 6.6% | |

| Market Size in 2022 | USD 20.81 Billion | |

| Market Size by 2032 | USD 38.47 Billion | |

| Base Year | 2022 | |

| Forecast Period | 2023 to 2032 | |

| Equipment Segment Share in 2022 | 59.37 | % |

| Services Segment Growth Rate from 2023 to 2032 | CAGR of 7.7% | |

| Segments Covered | By Type, By Substrate, By Process, By End User, and Geography | |

We've prepared a service to help you write your own Go-To-Market strategy.

Click to Unlock Your GTM Strategy for the Physical Vapor Deposition (PVD) Market

Report Highlights:

Type Insights

The equipment segment is expected to dominate the market during the forecast period. The manufacturers of surface coatings are working to reduce carbon emissions and implement environmentally friendly procedures. Due to the advantages of PVD's reduced carbon footprint, surface coating businesses all over the world have a significant demand for PVD equipment. PVD coating is accomplished by using high-quality equipment that enables process optimization. To support the growth of the global PVD market soon, the manufacturers are developing application-specific PVD equipment for big die and broaches, automotive components, high-estimate tool coatings, and decorative coatings.

In addition, the competitors in the physical vapor deposition market are working on developing magnetron sputtering systems, which are employed in the deposition of several kinds of films, including tungsten, gold, platinum, and aluminum alloys, on wafers. This reason is expected to propel the physical vapor deposition market's growth in the PVD equipment sector globally.

Substrate Insights

The plastics segment is expected to grow at a rapid rate over the forecast period. Plastic components frequently have PVD coatings added to them for aesthetic reasons. These coatings may give objects like consumer goods, automobile interiors, and electronic gadgets a metallic look that adds quality and aesthetic appeal. Furthermore, plastics may not be as durable as other materials, however, PVD coatings can increase their resilience. Plastic components may be made more durable and resistant to wear by coating them with compounds like chromium nitride (CrN) or titanium nitride (TiN). This allows for uses in consumer goods and the automotive industry.

Customize this study as per your requirement@ https://www.precedenceresearch.com/customization/2285

Market Dynamics:

Drivers: Growing demand for solar panels

Multiple governments across the globe are planning to switch to renewable energy sources due to the worsening environmental circumstances and global depletion of conventional fuel. The quick urbanization and industrialization of society, together with the increased need for fuel for electricity production, have all greatly increased carbon emissions. As the globe shifts to using renewable energy sources, the demand for solar panels is being driven by increased government measures to reduce carbon emissions. PVD is widely used in solar panels to increase their lifespan and resistance to corrosion. Thus, the growing demand for solar panels drives the market expansion during the forecast period.

Restraint: High capital investment

To create high-quality graphene using vapor deposition, certain equipment is needed, and parameters regarding gas volumes, pressure, temperature, and time intervals must be closely followed. Throughput and productivity are increased by processing many substrates in parallel using the cluster tool system. Typical setups include a transfer chamber, several process chambers that can execute one or more processes, and a load lock chamber for loading substrates. Using a robotic arm, the substrates are moved between chambers while under vacuum to keep them from coming into contact with air, which stops oxidation and contamination. The high initial cost of all of them serves as a barrier to the physical vapor deposition business.

Opportunity: Growth of the automotive industry

The automotive industry uses PVD for various applications, including decorative coatings, wear-resistant coatings, and improving the durability of automotive components. As the automotive sector continues to grow, so does the demand for PVD technologies. For instance, according to the European Automobile Manufacturers Association, 85.4 million motor vehicles were produced globally in 2022, a 5.7% increase from 2021. In addition, as per the data published by Invest India, the total amount of autos exported grew positively by 35.9%, from 4,134,047 in 2020–21 to 5,617,246 in 2021–22. It is anticipated that by 2050, the trucking market in India will have expanded by more than 4 times. By 2050, there will be around 17 million trucks worldwide, more than quadrupling from 4 million in 2022.

Related Reports:

- Chemical Vapor Deposition Market: The global chemical vapor deposition market size was estimated at USD 26 billion in 2022 and is expected to hit around USD 59.05 billion by 2032 with a notable CAGR of 8.6% during the forecast period 2023 to 2032.

- Atomic Layer Deposition Market: The global atomic layer deposition market was valued at USD 2.09 billion in 2022 and is expected to hit USD 6.59 billion by 2030, growing at a noteworthy CAGR of 15.4% during the forecast period 2023 to 2030.

- Nanocoatings Market: The global nanocoatings market reached USD 12 billion in 2022 and is expected to hit USD 66.35 billion by 2032 with a compound annual growth rate (CAGR) of 18.7% from 2023 to 2032.

- Carbon Nanomaterials Market: The global carbon nanomaterials market size reached USD 3.6 billion in 2022, and it is expected to be worth around USD 40.71 billion by 2032, growing at a CAGR of 27.5% during the forecast period from 2023 to 2032.

- Carbon Nanotubes Market: The global carbon nanotubes market size accounted for USD 2 billion in 2022 and it is expected to surpass around USD 7.71 billion by 2032 with a registered CAGR of 14.50% during the forecast period 2023 to 2032.

Recent Developments:

- In January 2022, the purchase of a Hauzer Flexicoat 1500 PVD system by IHI Ionbond signifies a substantial investment in decorative coating capabilities. This massive coating machine has an amazing 1.5 m by 0.9 m coating zone. It is a welcome addition to the expanding capabilities of the Ionbond component coating factory located in Consett County, Durham.

Market Key Players:

- Kobe Steel Ltd.

- Lafer S.p.A.

- Kurt J. Lesker Company

- Voestalpine AG

- NISSIN ELECTRIC Co., Ltd

- IHI Corporation

- HEF Groupe

- Oerlikon Group

- Angstrom Engineering Inc.

- Inorcoat

Market Segmentation

By Type

- Materials

- Equipment

- Services

By Substrate

- Metals

- Plastics

- Glass

By Process

- Thermal Evaporation

- Sputtering

- IonPlating

By End User

- Electronics Semiconductors

- PCBs

- Display Panels

- Others

- Automotive

- Engine Components

- Wheels & Rims

- Lighting Systems

- Others

- Aerospace & Defense

- Aircraft Components

- Satellite Parts

- Military Equipment

- Healthcare

- Medical Devices

- Surgical Instruments

- Dental Tools & Implants

- Energy

- Solar Panels

- Fuel Cells

- Packaging

- Industrial

- Cutting Tools

- Machine Components

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa (MEA)

You can place an order or ask any questions, please feel free to contact us at

sales@precedenceresearch.com | +1 650 460 3308

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/2285

Unlocking Market Insights through Data Excellence

The "Precedence Statistics" flexible dashboard is a powerful tool that offers real-time news updates, economic and market forecasts, and customizable reports. It can be configured to support a wide range of analysis styles and strategic planning needs. This tool empowers users to stay informed and make data-driven decisions in various scenarios, making it a valuable asset for businesses and professionals looking to stay ahead in today's dynamic and data-driven world.

To Access our Premium Real-Time Data Intelligence Tool, Visit:

www.precedencestatistics.com

About Us

Precedence Research is a worldwide market research and consulting organization. We give an unmatched nature of offering to our customers present all around the globe across industry verticals. Precedence Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures present globally.

Web: https://www.precedenceresearch.com/

Our Blogs:

https://www.towardshealthcare.com

https://www.towardspackaging.com

For Latest Update Follow Us: