Boulder, Feb. 21, 2024 (GLOBE NEWSWIRE) -- If you own a commercial building or manage a commercial property, one of your top priorities must be ensuring critical systems like plumbing and electrical function as designed. That includes providing tenants access to potable water and ensuring that drinking water flows into your building but never back into the municipal water supply. That one-way flow is required under government regulations and is strictly enforced.

A key component in meeting clean water standards is a device called a backflow preventer. What is a backflow preventer, and why is it so important? This article answers those questions and explains why regular inspections by a skilled plumber are essential. It also describes what to expect in a backflow preventer inspection.

What Is a Plumbing Backflow Preventer?

In plumbing, “backflow” is a very undesirable condition. The term is used to describe a situation where water that should be moving in a particular direction moves in the opposite direction. Allowing backflow can create a public health crisis, as it potentially lets chemicals, waste and other dangerous substances make their way into a community’s potable water supply.

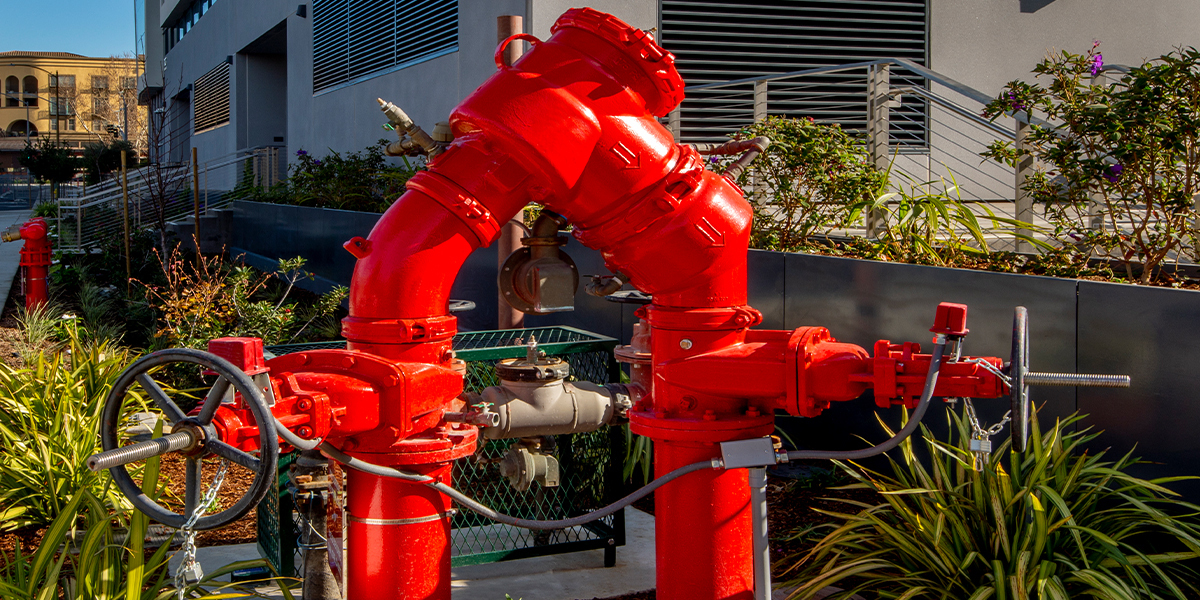

A backflow preventer does precisely what its name suggests: It keeps water that has entered a commercial building (or any building) from flowing back out of it through the same pipe. Essentially, it is a one-way gate that lets inbound water enter a building but immediately stops it if it detects a change in flow direction.

Backflow preventers are typically placed at every cross-connection point in plumbing systems. The device used varies depending on the types of hazards present in the building. Types of backflow preventers include:

- Air gap preventers

- Pressure vacuum breakers

- Reduced pressure principle systems

- Atmospheric vacuum breakers

- Double-check valves

Generally speaking, the potable water flowing to your commercial building is under pressure that keeps it moving in the appropriate direction. However, that dynamic can change for either of two main reasons:

- Back pressure. This is when the pressure within a commercial property’s plumbing system exceeds the pressure of the municipal water distribution lines. Common causes include using boilers, recirculating systems or pumps used to move water to higher floors.

- Back siphonage. Events like a break in the main water line can create pressure changes that pull water out of a building. There is also the potential for siphonage during high water withdrawal situations, like during firefighting operations.

Regardless of the cause, backflow is a significant problem. Consequently, ensuring a backflow preventer works correctly isn’t simply an operational issue. It’s a safety issue, and there can be significant legal and financial ramifications when a backflow preventer malfunctions or fails. You might even have water service to your building temporarily discontinued until you address your plumbing issues. That means backflow preventer inspections must be performed by trained experts and completed when and how local ordinances dictate.

What Happens in a Plumbing Backflow Preventer Inspection?

When performing a backflow preventer inspection, the technician does the following:

- Closes the downstream shutoff valve

- Waits briefly

- Assesses system pressure using a test kit

- Opens and closes various valves to check for irregularities

- Looks for leaks or other signs of plumbing problems

Typically, no preparation is required of building owners or property managers other than ensuring that the expert has access to the building’s plumbing infrastructure. The person scheduling the inspection should notify building occupants that the water supply will be interrupted for a short time—typically 20 to 30 minutes if no immediate system repairs are needed.

Minor problems may be addressed immediately, However if issues that require significant repairs are detected, you may need to schedule a separate visit for that work.

When Are Backflow Preventer Inspections Required?

As a commercial building owner or property manager, it’s vital that you understand the rules and regulations regarding backflow preventers in your area. Typically, inspections are required:

- When plumbing systems are installed or relocated

- When plumbing system components are replaced

- Annually, for existing systems

In addition, you should schedule a backflow preventer inspection if you notice any indicators of a potential problem, including:

- Changes in your water’s color, smell or taste

- Changes in water pressure

- Outbreaks of illnesses that can be waterborne

A “better safe than sorry” approach is advisable with plumbing systems in commercial buildings. The time and cost involved in a backflow preventer inspection is significantly less than you will experience if you don’t detect and correct problems with your backflow preventer.

Remember that the “costs” can be more than financial. Failing to protect building occupants or community residents from exposure to contaminated water can damage your reputation and cause you to lose future business opportunities. On the other hand, being proactive shows you care about safety and can elevate your standing as a responsible property owner.

Have Your Commercial Plumbing System and Backflow Preventer Inspected by Timberline Mechanical

Our plumbing services team at Timberline Mechanical is a group of skilled professionals that includes an experienced master plumber. Commercial property owners rely on us for a wide variety of services on all types of plumbing system components, such as water lines, sinks and faucets, water heaters and water fountains. That includes expert backflow preventer inspections, service and certification.

Whether you are installing or adding plumbing infrastructure, need an annual inspection or suspect there may be a problem with your backflow preventer, we can help. And as every commercial property owner or manager can attest, it’s reassuring to know where to turn with plumbing issues in general.

If you’re not already a Timberline customer, we encourage you to learn more about our services. Then, contact us if you have questions or want to schedule a one-time project or recurring preventative maintenance.

We also have extensive expertise in commercial and industrial HVAC systems. Get in touch today, and let’s discuss how to ensure your facility operates at peak efficiency.

About Timberline Mechanical

Timberline Mechanical is a Boulder HVAC Contractor located in Boulder, CO, and serving the Colorado Front Range, including Broomfield, Longmont, Louisville, Lafayette, Superior and Erie. We are dedicated to providing the intelligent solutions necessary to keep your Boulder Commercial HVAC equipment running efficiently and at its peak performance. Whether we are completing a service call request, providing Commercial HVAC Preventive Maintenance or conducting Special Projects work, we offer intelligent commercial HVAC solutions to ensure that your business needs are met. You can focus on your business while we make sure your commercial HVAC equipment is running smoothly. https://www.timberlinemechanical.com/

John Kuepper

Media Contact: 303-258-3589