Shenzhen , June 14, 2024 (GLOBE NEWSWIRE) -- As an expert in the laser industry, Hymson has dedicated 16 years to laser application. It has accumulated profound expertise in product development and the integration of laser technology with automation, and has successfully deployed over a hundred types of high-end equipment in the LIB industry. Hymson was the first in China to develop a laser tab welding machine, and pioneered the application of laser notching machine in the mass production of LIB. By harnessing the prowess of laser technology, Hymson is at the forefront of the development of fully automated high-speed assembly lines as well as revolutionizing LIB manufacturing, driving the industry towards higher efficiency and superior quality. At The Battery Show Europe, Hymson will unveil its latest breakthroughs in battery intelligent manufacturing solutions, alongside its team of laser specialists, to explore the battery innovation through cutting-edge laser solutions.

New Insights: Tech Talk from Hymson Laser Experts, Pioneering New Era of Lithium Battery Manufacturing

Hymson boasts a team of laser experts. Davis Li is a senior engineer renowned for his over a decade of innovative contributions to LIB R&D and implementation. He has secured over 30 patents. Ronald Zhang, an optical engineering specialist, who has been engaged in cutting-edge laser research at a prestigious optical institute in China for over a decade, and has delivered numerous innovative solutions to the lithium-ion industry. Tyler Tan is a LIB equipment expert with over 12 years of experience in renowned German companies. He has rich experience in large-scale powertrain assembly and LIB assembly line planning and design. Tinghui Hu, an automotive R&D expert, leverages extensive experience from both Chinese and Germany companies to offer forward-looking insights into the automotive industry in China and Europe, particularly in the area of LIB manufacturing equipment. These four experts will converge at the exhibition to share cutting-edge knowledge in laser LIB technology and address any inquiries visitors may have on-site.

Also, Hymson will deliver six unique and insightful tech talks, aiming to address the pain points in LIB manufacturing, such as low efficiency, high costs, and low yield rates. From driving the LIB market with lasers, initiating a green revolution through laser technology, to the integration of digital intelligent systems with laser technology, Hymson aims to assist the LIB industry in embracing a new era of digitization and intelligence. The six tech talks will begin at 10:40 AM and conclude at 4:30 PM on June 18th and 19th.

New Technologies: Hymson Laser Applications Reduce Cost and Improve Efficiency in LIB Intelligent Manufacturing

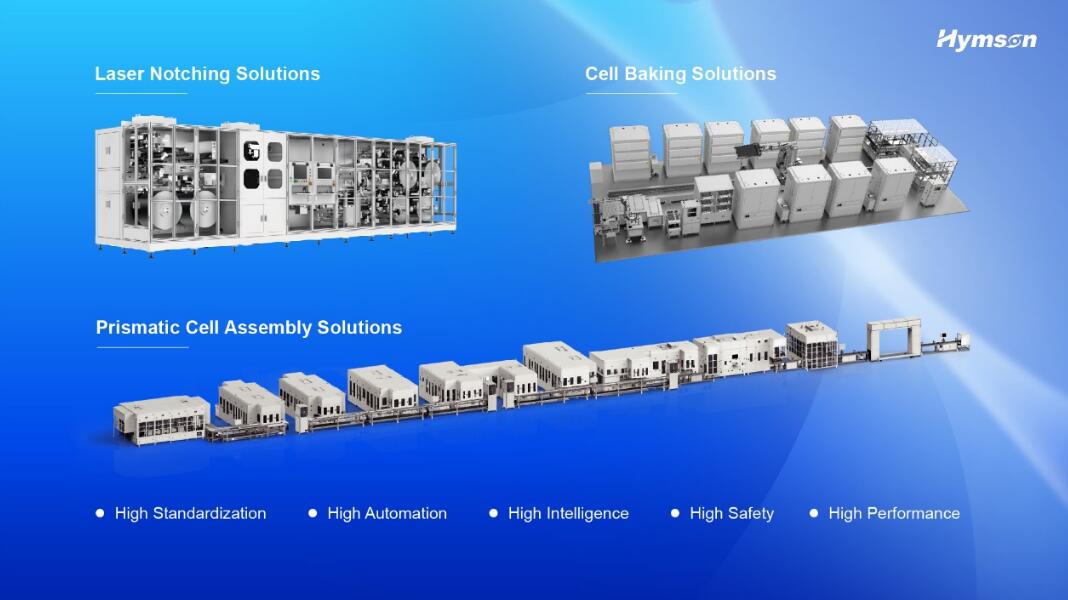

Hymson has a robust R&D system with advanced laser and automation technology, enabling it to provide customers with comprehensive solutions and support to Lithium-ion battery manufacturing. At this exhibition, Hymson will showcase its ultra-high-speed electrode tab notching process with a cutting speed of 120-200 m/min, burr precision ≤ 20 μm and HAZ ≤ 100 μm. This process demonstrates outstanding compatibility, accommodating various tab shapes, materials, and thicknesses. It also boasts short commissioning cycles and low maintenance costs. In terms of product safety and stability, it efficiently solves technical challenges in electrode production, such as powder accumulation, laser cutting failure, web breakage, and foreign objects. Also, Hymson has made significant breakthroughs in core laser technologies including marking traceability, which will further lower cost and enhance efficiency in lithium battery manufacturing, while also improving front-end quality.

With a profound understanding of laser applications and long-term R&D investment, Hymson excels in intelligent cell assembly equipment solutions. Its connector-free tab welding technology and ultra-high-speed lid welding technology surpass industry standards. By utilizing Hymson self-developed laser, in-line welding inspection, CT inspection, and other techniques, it further enhances production line reliability and reduces cell manufacturing costs.

Moreover, leveraging advanced baking scheduling systems, Hymson has introduced a fully automatic vacuum baking line. This line integrates scheduling systems with vacuum baking ovens, achieving high flexibility, full automation, and intelligence in the cell baking process. By enhancing the efficiency and quality of the baking production line, it effectively addresses industry pain points such as incomplete baking, low efficiency, and high costs. With outstanding R&D and innovation competitiveness, Hymson are driving LIB laser manufacturing towards low cost, high safety, high energy density, and long cycle life, boosting high quality productivity.

Caring Service: Hymson's Complete Production Line Scale Model Display, Sample Testing Services, and Happy Hour

During The Battery Show Europe, Hymson will debut its complete line of LIB intelligent manufacturing solution in the form of scale model. With product models and lighting effects, the battery production process will be visually presented to help customers understand process layouts, equipment configurations, production line operation principles, and automation.

Additionally, Hymson will open appointments for on-site sample testing activities, aiming to showcase the quality, appearance, and overall effect. This initiative assists in previewing and confirming the final form of the product before actual production, thereby minimizing the possibilities for misunderstanding and rework, and saving time and resources for customers. In the meantime, for the first two days of the exhibition, Hymson will host a unique cocktail event at its booth – the Hymson Happy Hour. Local European bartenders will be invited to craft a variety of European cocktails (such as Aperol and Lilyberry) and serve an assortment of snacks, creating a relaxed and enjoyable atmosphere for visitors.

With in-depth expert sharing, vivid scale models, insightful tech talks, and relaxing Happy Hour to offer, Hymson sincerely invites you to visit its booth. It will have mutual exchange and discuss how to empower the battery industry's green transformation and intelligent manufacturing through innovative laser technology.

Visit Hymson at Messe Stuttgart, Germany from June 18th to 20th in Hall 8, booth D70&80!

For more information, please click the link: https://global.hymson.com/EN/batteryshow.html

About Hymson

Hymson Laser Technology Group Co., Ltd. was established in 2008 and listed on the Science and Technology Innovation Board (STAR Market) in 2020 with the stock code 688559. As a leading provider of laser and automation solutions, Hymson excels in EV Batteries, Photovoltaics, Micro LED, Consumer Electronics, and Sheet Metal.

Hymson is headquartered in Shenzhen, China, with four manufacturing bases in Shenzhen, Jiangmen, Changzhou, and Chengdu, covering the South China, East China, and Southwest China regions. Hymson has also established overseas subsidiaries in South Korea, the United States, Italy, the Netherlands, Germany, Switzerland, and Singapore to accelerate global expansion.

In the era of Industry 4.0, Hymson always remembers its mission of "Transforming the Global Equipment Landscape, Advancing Human Intelligent Manufacturing." By focusing on cutting-edge technologies, Hymson drives industrial transformation and collaborates closely with its global customers to shape the future of intelligent manufacturing.

Official Website: https://global.hymson.com