Austin, Dec. 08, 2024 (GLOBE NEWSWIRE) -- Market Size & Growth Analysis:

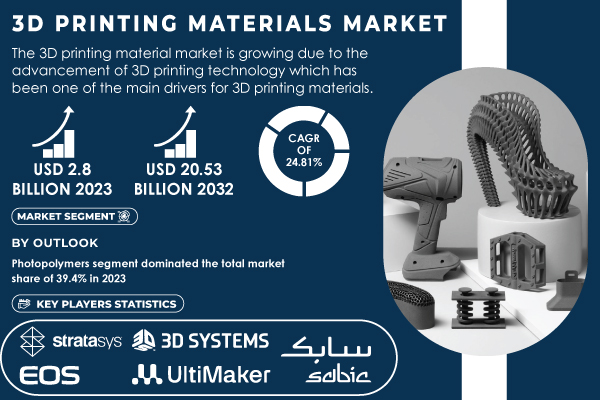

The SNS Insider report indicates that,“The 3D Printing Materials Market Size was valued at USD 2.8 Billion in 2023 and is expected to reach USD 20.53 Billion by 2032 and grow at a CAGR of 24.81% over the forecast period 2024-2032.”

3D Printing Materials Driving Efficiency and Precision across Industries

The growth of the 3D printing materials market is driven by advancements in 3D printing technology, enabling industry-specific material diversification based on origin, composition, and performance. Metals, valued for high-temperature resistance, are widely used in aerospace and automotive, reducing air drag, fuel costs, and component weight significantly. Polymers dominate household appliance manufacturing due to cost efficiency. For example, 3D-printed aircraft components can cut fuel costs by 5.41% and reduce lead times by up to 90% for jigs and fixtures. Additionally, 3D printing minimizes waste by up to 40% in metal applications. With increasing adoption in biomedical and healthcare sectors, demand for medical-grade materials for prosthetics and implants is poised to grow exponentially.

Get a Sample Report of 3D Printing Materials Market Forecast @ https://www.snsinsider.com/sample-request/4908

Dominant Market Players with their Products Listed in this Report are:

- Stratasys (ABS, PLA)

- 3D Systems (SLA Resin, Nylon)

- EOS (PA12, AlSi10Mg)

- Materialise (Magenta, MJP Resin)

- HP (Nylon 12, TPU)

- Formlabs (Tough Resin, Grey Resin)

- Ultimaker (PLA, Nylon)

- Sabic (ULTEM 9085, PETG)

- Arkema (Rilsan, Kepstan)

- BASF (Ultrafuse PLA, Ultrafuse TPU)

- SABIC (Lexan, ULTEM)

- Mitsubishi Chemical (Filament, Resin)

- LG Chem (Polycarbonate, ABS)

- Eastman Chemical Company (Tritan, Amphora)

- RTP Company (RTP 3000, RTP 6000)

- Nexa3D (Xtreme 8K Resin, XCE White Resin)

- Xerox (Xerox 3D Printing, Filament)

- Polymaker (PolyMax PLA, PolySupport)

- ColorFabb (ColorFabb PLA, ColorFabb PETG)

- Reprapper (ABS, PLA)

- Axtra 3D.

Revolutionizing Manufacturing with the Power of Localized 3D Printing for Faster and Sustainable Production

Localized 3D printing is transforming manufacturing by reducing long supply chains and accelerating production. For instance, General Electric reduced the complexity of its jet engine fuel nozzle from 20 parts to just one, cutting lead times from 30 weeks to only three. This innovation is particularly beneficial for industries like aerospace and automotive, where rapid prototyping and on-site production are increasingly important. Companies such as Airbus are leveraging 3D printing to reduce lead times for specific components by up to 90%. By 2030, Airbus plans to integrate additive manufacturing for 20% of its parts, further enhancing efficiency and sustainability.

Growth Dynamics in the 3D Printing Materials Market Insights by Outlook and Application

By Outlook

The Photopolymers segment dominated the 3D printing materials market in 2023, capturing a 39.4% share due to its ability to create intricate models, prototypes, and end-use objects with high precision and smooth finishes. Widely used in industries like dentistry, jewelry, and electronics, photopolymers are valued for their quick curing time and detailed resolution.

Meanwhile, the Thermoplastics segment is expected to grow at a high CAGR from 2024 to 2032, driven by its durability, flexibility, and resistance to high temperatures. Increasing adoption in automotive, aerospace, and consumer goods industries, alongside a push for environmentally friendly materials, is fueling its rapid growth.

By Application

The Automotive segment led the 3D printing materials market with a 30.6% share in 2023, driven by its application in prototyping, tooling, and manufacturing end-use parts. This technology streamlines design processes, reduces lead times, and minimizes waste and costs. In markets like BRIC, manufacturers are focusing on composite thermosetting parts and lightweight components to enhance performance efficiency.

The Aerospace And Defense segment is set to grow rapidly from 2024 to 2032, leveraging 3D printing for lightweight, complex components that improve fuel efficiency and performance. On-demand manufacturing optimizes supply chains, while advanced materials meet stringent aerospace safety and performance standards.

Do you Have any Specific Queries or Need any Customize Research on 3D Printing Materials Market, Request for Analyst Call @ https://www.snsinsider.com/request-analyst/4908

Key Market Segments:

By Outlook

- Photopolymers

- Thermoplastic

- Metals

- Others

By Application

- Automotive

- Aerospace & Defense

- Consumer Products & Industrial

- Medical

- Others

North America Leads 3D Printing Materials Market While Asia Pacific Emerges as Fastest-Growing Region

In 2023, North America led the 3D printing materials market with a 36% share, driven by its advanced manufacturing infrastructure and significant investments in research and development. The region is home to major industry players like Stratasys, a global leader in 3D printing solutions, and key automotive manufacturers such as Ford and General Motors. These companies have accelerated the adoption of 3D printing for both prototyping and production, solidifying North America’s leadership in the market.

The Asia Pacific region is set to become the fastest-growing market from 2024 to 2032, particularly in China and Japan. In China, companies like SANY Heavy Industry are using 3D printing to develop large machinery parts, while Japan’s Mitsubishi applies the technology to enhance aircraft production and customization.

Purchase an Enterprise User License of 3D Printing Materials Market Report at 40% Discount @ https://www.snsinsider.com/checkout/4908

Recent Development

- September 11, 2024 – Stratasys has unveiled the Origin Two DLP Printer, paired with the Origin Cure post-processing system, designed to deliver injection-molding quality for short production runs. The printer offers precision with an accuracy of +/- 50 µm, suitable for applications in connectors, aerospace, and automotive sectors, while its heated chamber supports materials with up to 300°C Heat Deflection Temperature.

- March 21, 2024 – EOS has introduced the EOS M 290 1kW, a new Laser Powder Bed Fusion (LPBF) metal 3D printer designed for serial production. This platform, tailored for processing copper and copper alloys, is already qualified for EOS Copper CuCp and EOS Copper CuCrZr materials, with more materials expected in 2024. GBZ Mannheim GmbH & Co.KG is among the first adopters, using the technology for producing heat exchangers and inductors for the automotive sector.

Table of Contents - Key Points Analysis

1. Introduction

2. Executive Summary

3. Research Methodology

4. Market Dynamics Impact Analysis

5. Statistical Insights and Trends Reporting

5.1 3D Printing Materials Sustainability Metrics, by Region, (2020-2023)

5.2 3D Printing Materials Pricing Trends, by Region, (2020-2023)

5.3 3D Printing Materials Technological Adoption Rates, by Region

5.4 3D Printing Materials Supply Chain Metrics, by Region (2023)

6. Competitive Landscape

7. 3D Printing Materials Market Segmentation, by Outlook

8. 3D Printing Materials Market Segmentation, by Application

9. Regional Analysis

10. Company Profiles

11. Use Cases and Best Practices

12. Conclusion

Access Complete Report Insights of 3D Printing Materials Market Growth & Outlook 2024-2032@ https://www.snsinsider.com/reports/3d-printing-materials-market-4908

[For more information or need any customization research mail us at info@snsinsider.com]

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.