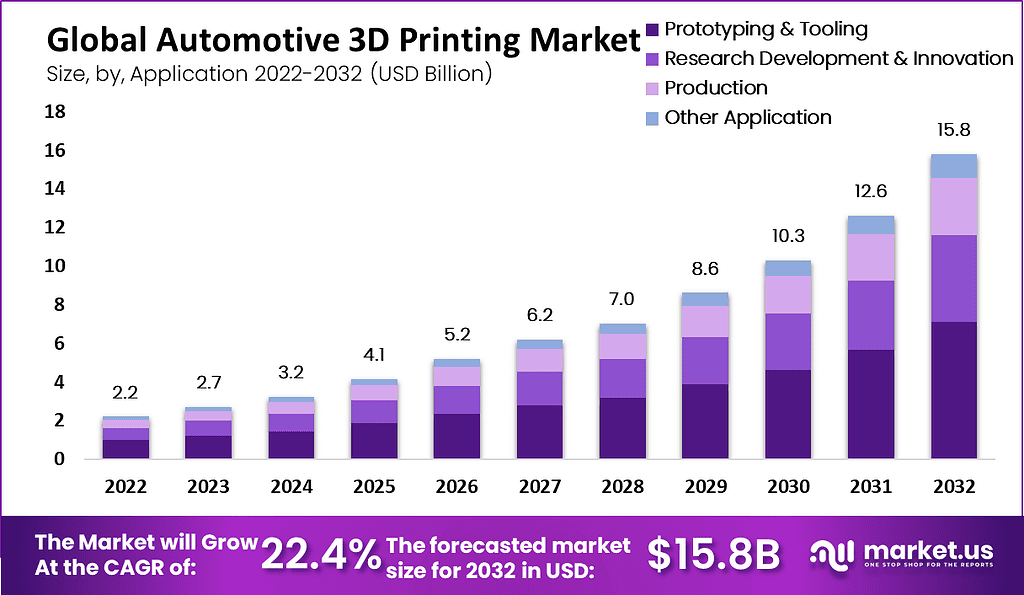

New York, April 12, 2023 (GLOBE NEWSWIRE) -- The Global Automotive 3D Printing Market size is expected to be worth around USD 15.8 Billion by 2032 from USD 2.2 Billion in 2022, growing at a CAGR of 22.4% during the forecast period from 2022 to 2032.

Automotive 3D printing refers to the use of 3D printing technology to produce parts and components for automobiles. This technology includes using a computer-aided design model to create a physical object by adding layers of material, especially plastic or metal. In the automotive industry, 3D printing has the potential to revolutionize the manufacturing process by allowing for the rapid production of customized parts, minimizing the need for expensive tooling, and enabling parts to be produced on demand which reduces the need for inventory and improves production efficiency. Overall, the use of 3D printing in the automotive industry is expected to grow as more companies realized the benefits it can offer which include improved design capabilities, greater sustainability, and cost savings.

To get additional highlights on major revenue-generating segments, Request an Automotive 3D Printing Market sample report at https://market.us/report/automotive-3d-printing-market/request-sample/

Key Takeaway:

- Based on application, in 2022, the automotive 3D printing market was dominated by the prototype & tooling segment owing to its straightforward process.

- Based on technology, in 2022, the fused deposition segment accounted for 28.5% market share.

- By material, in 2022, the plastic segment dominated the market with a 43.3% share of the material segment.

- By vehicle type, in 2022, the ICE vehicle segment dominated the largest market share in the vehicle type segment.

- Based on offerings, in 2022, the hardware segment accounted for the largest offerings segment in the automotive 3D printing market.

- By component, in 2022, the exterior component dominated the market with a 60.7% share.

- In 2022, North America dominated the market with the highest revenue share of 38.9%.

- APAC is expected to have the highest CAGR among all regions, owing to its rapidly developing infrastructure, new start-ups, government efforts, low-cost raw materials, developed chemical industries, etc.

Factors affecting the growth of the Automotive 3D Printing Market

There are several factors that can have an impact on the growth of the automotive 3D printing industry including:

- Customization: 3D printing enables the production of highly customized products that can be tailored to meet specific customer requirements, like unique car parts or personalized car designs.

- Advancement in technology: The development of new 3D printing technologies and materials has significantly improved the capabilities of 3D printing for automotive applications like creating lightweight and durable parts.

- Cost-effective manufacturing: 3D printing is a more cost-effective manufacturing solution for producing low-volume and high-volume parts as it removes the need for expensive tooling.

- Sustainability: The use of 3D printing can help to reduce waste and energy consumption by using only the necessary materials for producing parts, as it makes the industry more sustainable.

- Speed: 3D Printing enables faster prototyping and production, which is crucial for meeting the growing demand for faster production cycles.

To understand how our report can bring a difference to your business strategy, Inquire about a brochure at https://market.us/report/automotive-3d-printing-market/#inquiry

Market Growth

Many factors drive the growth of the automotive 3D printing market, as the 3D printing market has been experiencing the fastest growth in the last few years, and this is projected to continue in the coming years. The factors include the increased adoption of 3D printing technologies in automotive for the production of prototypes, tools, and parts are driving the market. Growing demand for lightweight and customized automotive parts and cost-effective manufacturing solutions offered by 3D printing technology for low-volume, high-value parts production are also key driving factors. Government initiatives & Technological advancements, and investments in the automotive 3D printing industry to promote the adoption of advanced manufacturing technologies. Collaboration & partnerships between 3D printing technology providers and automotive manufacturers for developing & producing customized parts & prototypes.

Regional Analysis

North America is accounted as the most dominant market in the global automotive 3D printing market, during the forecasted period. Due to the huge number of OEM manufacturers which are investing the majority of their revenue in R&D., Many automobile manufacturers are investing their funds in these technologies for creating customized automotive parts and also to reduce manufacturing costs, reduce material waste, enhance production rate, and less turnaround time.

Have Queries? Speak to an expert or Click Here To Download/Request a Sample

Scope of Report

| Report Attribute | Details |

| Market Value (2022) | USD 2.2 Billion |

| Market Size (2032) | USD 15.8 Billion |

| CAGR (from 2023 to 2032) | 22.4% from 2023 to 2032 |

| North America Revenue Share | 38.9% |

| Historic Period | 2016 to 2022 |

| Base Year | 2022 |

| Forecast Year | 2023 to 2032 |

Market Drivers

The factors which drive the growth of the automotive 3D printing market include, the use of 3D printing technologies in the automotive sector has allowed original equipment manufacturers (OMEs) to minimize costs and produce parts in less time. Despite beginning challenges with implementing the technology, OEMs have reported positive effects on their production processes and tend to increase investments in 3D printing. This has led to significant R&D investments in 3D printing technology by companies for introducing new and innovative 3D printing technologies for automotive applications.

Market Restraints

The primary restrain for 3D printing is the additional cost of the materials used in the process of 3D printing. This cost is driven by the need for a top level of purity & consistency in composition & size, these are necessary for specific 3D printing techniques. The absence of well-established standards for the mechanical properties of these materials also discourages manufacturers from incorporating 3D-printed components into their final products owing to problems with reliability and accuracy.

Market Opportunities

The development of 3D printing has evolved from only producing prototypes to directly manufacturing finished goods, which is leading to an increased interest in the potential future applications of this technology in various sectors like healthcare, automotive, and consumer products. The commercial possibilities of 3D printing are significant, and it is expected to have a significant impact on a wide range of industries, including aerospace and medical fields. With increasingly complex and personalized applications anticipated in the near future, create more opportunities for the key players operating in the 3D printing industry.

Grow your profit margin with Market.us - Purchase This Premium Report at https://market.us/purchase-report/?report_id=60731

Report Segmentation of the Automotive 3D Printing Market

Application Type Insight

Based on the applications, the automotive 3D printing market is dominated by the prototype & tooling segment, owing to the quick production of the prototype, cost reduction, straightforward process, choices of filaments that could be used, design changes, and minimizing wastage. The prototypes now require the shortest possible lead times and less expense and wastage.

Technology Insight

Based on technology, the automotive 3D printing market is dominated by the fused deposition modeling segment, due to its ability to produce large parts with high strengths and durability at low cost. The technology involves the use of a thermoplastic filament which is melted and deposited layer by layer to create a 3D object. FDM is suitable for producing a wide range of automotive parts which includes, fixtures, jigs, and tooling. Additionally, FDM can produce parts with high strength and stiffness and making it an attractive option for producing functional end-use parts

Material Insight

Based on material the automotive 3D printing market is dominated by the plastic segment, due to its low cost, ease of use, and ability to produce complex geometrics. Furthermore, plastic materials have a wide range of properties that can be tailored to specific applications. For instance, ABS is often used for interior parts, whereas nylon is commonly used for functional parts.

For more insights on the historical and Forecast market data from 2016 to 2032 - download a sample report at https://market.us/report/automotive-3d-printing-market/request-sample/

Key Market Segments:

Based on Application

- Prototyping & Tooling

- Research Development & Innovation

- Production

- Other Applications

Based on Technology

- Stereo Lithography

- Selective Laser Sintering

- Electronic Beam Melting

- Fused Deposition Modelling

- Laminated Object Manufacturing

- Three-Dimensional Inject Printing

- Other Technologies

Based on Materials

- Metals

- Stainless Steel

- Titanium

- Aluminium

- Metal Alloys

- Plastic

- Acrylonitrile Butadiene Styrene

- Polylactic Acid

- Nylon

- Composites and Resins

- Other Materials

Based on Vehicle Type

- ICE Vehicles

- Electric Vehicles

By Offering

- Hardware

- Software

By Component

- Interior Components

- Exterior Components

By Geography

- North America

-

- The US

- Canada

- Mexico

- Western Europe

-

- Germany

- France

- The UK

- Spain

- Italy

- Portugal

- Ireland

- Austria

- Switzerland

- Benelux

- Nordic

- Rest of Western Europe

- Eastern Europe

-

- Russia

- Poland

- The Czech Republic

- Greece

- Rest of Eastern Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia & New Zealand

- Indonesia

- Malaysia

- Philippines

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

-

- Brazil

- Colombia

- Chile

- Argentina

- Costa Rica

- Rest of Latin America

- Middle East & Africa

-

- Algeria

- Egypt

- Israel

- Kuwait

- Nigeria

- Saudi Arabia

- South Africa

- Turkey

- United Arab Emirates

- Rest of MEA

Competitive Landscape

Due to the presence both of established and startups, the automotive 3D printing market remains fragmented. Voxeljet AG and Stratasys Ltd. are some of the major players in the global automotive 3D printer market. These players invest heavily in technology development to produce the most advanced materials and methods that will enable automotive companies to create products with enhanced material properties in a shorter time. They also engage in mergers and acquisitions to consolidate their position.

Recent Developments of the Automotive 3D Printing Market

- In November 2022, ExOne's parent company, Desktop Metal, announced that it won a US$9 Million order from a German manufacturer of car parts for their binder jet additive manufacturing system.

- In November 2022, ALM and 3D Systems announced a partnership in order to increase access to the best 3D printing materials. ALM will now offer DuraForm PAx material from 3D Systems to its customers. This unique copolymer is specifically designed for Selective Laser Sintering technology.

- In September 2022, Stratasys Ltd. has announced the completion of the merger between MakerBot, its subsidiary, and NPM Capital-Backed Ultimaker in order to create Ultimaker. NPM Capital will have a 53.5% share in the new company. Stratasys Ltd, on the other hand, will own the remaining 46.5%.

Key Market Players:

Listed below are some of the most prominent automotive 3D printing industry players.

- 3D Systems Corporation

- Autodesk Inc.

- Desktop Metal Inc.

- EOS GmbH

- General Electric Company

- Hoganas AB

- Materialise NV

- Stratasys Ltd.

- Ultimaker BV

- Voxeljet AG

- ExOne Company

- Arcam AB

- Renishaw plc.

- Amazon.com

- SLM Solutions Group AG

- Farsoon Technologies

- Sinterit

- Protolabs Electronics Pvt. Ltd.

- Nexa3D

- EPlus3D Tech GmbH

- Other Key Players

Browse More Related Reports:

- 3D Printing in the Education market was valued at USD 278.6 million in 2022 and is projected to increase significantly at a CAGR of 10% from 2022 to 2033.

- 3D Printing Metal Market size is expected to be worth around USD 5274.45 million by 2032 from USD 589.5 million in 2022, growing at a CAGR(compound annual growth rate) of 24.50% during the forecast period from 2023 to 2032.

- 3D printing materials Market size is expected to be worth around USD 17,775.07 million by 2032 from USD 1,624.16 million in 2021, growing at a CAGR of 24.30% during the forecast period from 2022 to 2032.

- 3D printing filament market accounted for USD 667.41 million in 2021. It is expected to grow at a CAGR of 19% between 2023 to 2032.

- 3D Printing Metal Market size is expected to be worth around USD 5274.45 million by 2032 from USD 589.5 million in 2022, growing at a CAGR(compound annual growth rate) of 24.50% during the forecast period from 2023 to 2032.

- 3D printing ceramics market was worth USD 50.68 million in 2021. It is projected to grow at a 35% CAGR between 2023 to 2032.

About Us:

Market.US (Powered by Prudour Pvt Ltd) specializes in in-depth market research and analysis and has been proving its mettle as a consulting and customized market research company, apart from being a much sought-after syndicated market research report-providing firm. Market.US provides customization to suit any specific or unique requirement and tailor-makes reports as per request. We go beyond boundaries to take analytics, analysis, study, and outlook to newer heights and broader horizons.

Follow Us On LinkedIn Facebook Twitter

Our Blog: