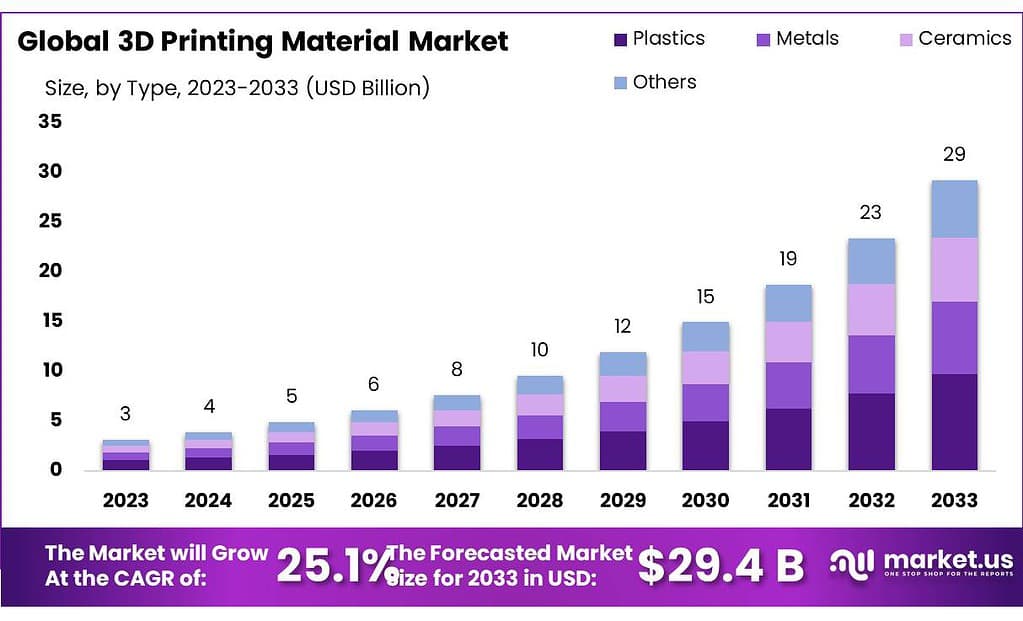

New York, Feb. 06, 2024 (GLOBE NEWSWIRE) -- According to Market.us, the Global 3D Printing Materials Market size is projected to reach USD 29.4 Billion by 2033 from USD 3.12 Billion in 2023, at a compound annual compound growth rate of 25.1% over its predicted lifespan between 2024-2033.

The 3D printing materials market refers to the industry involved in the manufacturing, production, and distribution of materials specifically designed and optimized for use in 3D printing processes. Also known as additive manufacturing, 3D printing is a technique that builds three-dimensional objects layer by layer from digital models. The success and efficiency of 3D printing technology depend significantly on the quality and characteristics of the materials used.

To Gain greater insights, Request a sample report @ https://market.us/report/3d-printing-materials-market/request-sample/

Important Revelation:

- Market Growth Projection: The 3D Printing Materials Market is set to reach USD 29.4 Billion by 2033, exhibiting a robust 25.1% CAGR from its 2023 value of USD 3.12 Billion.

- Material Types: Plastic materials, constituting 33.2% in 2023, dominate due to versatility and cost-effectiveness, prominently used in automotive and healthcare.

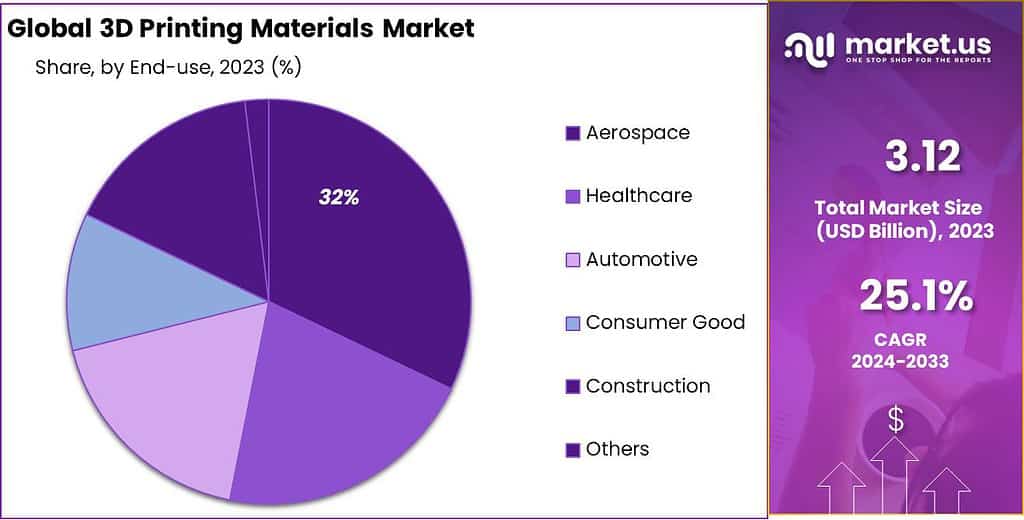

- End-Use Sectors: Aerospace & defense, holding a 33.4% share in 2023, relies on 3D printing materials for lightweight yet robust components. Medical applications contribute to market growth.

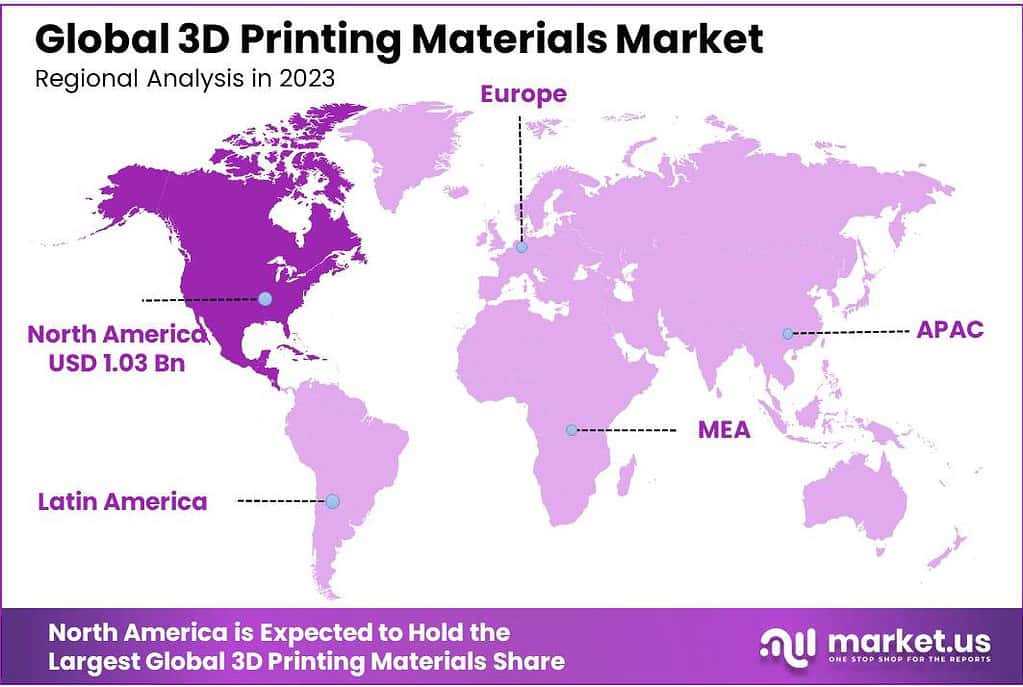

- Regional Analysis: North America, with a 32.1% market share in 2023, is poised for expansion, driven by increased investments and demand, particularly in metals for electronics, defense, aerospace, and automotive.

Factors Affecting the Growth of the Global 3D Printing Materials Market

- Technological Advancements: Continuous innovations in 3D printing technologies influence the demand for new and specialized materials, driving the growth of the market.

- Expanding Applications: Diverse applications in industries such as aerospace, healthcare, automotive, and consumer goods contribute to the market's expansion as 3D printing becomes integral to manufacturing processes.

- Material Performance: Growing demand for high-performance materials with specific properties, such as strength, flexibility, and biocompatibility, fuels the market's growth.

- Cost-Effective Solutions: The search for cost-effective and efficient manufacturing solutions boosts the adoption of 3D printing materials, particularly in industries where customization and small-batch production are essential.

- Increased Investments: Rising investments in research and development by key players and government initiatives supporting additive manufacturing technologies contribute to market growth.

Plan your Next Best Move. Purchase the Report for Data-driven Insights: https://market.us/purchase-report/?report_id=38164

Some of The Recent Developments 3D Printing Materials Market Are:

Höganäs AB:

- 2022: Signed a partnership with Linde Gas to develop new metal powders for additive manufacturing, particularly focusing on sustainability and cost-efficiency.

- 2023: Increased production capacity for metal powders at its facility in Sweden to meet growing demand.

3D Systems Corporation:

- 2022: Launched Figure 8 3D printing platform, emphasizing scalability and production-grade printing of industrial parts.

- 2023: Introduced high-detail resin for stereolithography (SLA) printers, ideal for jewelry, prototypes, and dental models.

- 2023: Acquired Oqton, a software company specializing in generative design, aiming to optimize parts for 3D printing.

General Electric (GE Additive)

- 2022: Launched Additive Manufacturing Consortium to accelerate the adoption of 3D printing in the aerospace industry.

- 2023: Expanded production capacity for metal powders at its facility in Ohio, focusing on high-performance materials.

- 2023: Partnered with SLM Solutions to develop new metal 3D printing systems with improved efficiency and productivity.

Кеу Market Рlауеrѕ

- Höganäs AB

- 3D Systems Corporation

- General Electric

- Arkema S.A.

- Royal DSM N.V.

- Stratasys Ltd.

- Evonik Industries AG.

- EOS GmbH

- Sandvik AB

- Other Key Major players

Scope of the Report

| Report Attributes | Details |

| Market Value (2023) | USD 3.0 Billion |

| Forecast Revenue 2033 | USD 29.4 Billion |

| CAGR (2024 to 2033) | 25.1% |

| North America Revenue Share | 32.1% |

| Base Year | 2023 |

| Historic Period | 2018 to 2022 |

| Forecast Year | 2024 to 2033 |

Request for Research Methodology to Understand Our Data-sourcing Process in Detail: https://market.us/report/3d-printing-materials-market/request-sample/

Report Segmentation

By Type

In 2023, plastic materials took the lead in the 3D printing materials market, claiming over 33.2% due to their versatility and cost-effectiveness, widely utilized in the automotive and healthcare industries. The market encompasses various materials, including photopolymers, thermoplastics, ceramics, and plywood filaments. Material selection is based on mechanical properties, manufacturing characteristics, appearance, and cost considerations. The rising demand for high-performance materials, particularly cost-effective thermoplastics, is driven by their lightweight yet resilient applications in aerospace, automotive, medical, and other sectors.

Metal alloys, such as titanium, aluminum, chrome, and cobalt, are preferred for dental implants, contributing to the market's growth. Additionally, the use of Laywood filament, made from recycled wood and polymer binding, is expanding, especially in industries adopting 3D printing technology for large architectural models, bowls, and sculptures. This diverse material landscape reflects the market's growth potential across various applications and industries.

By Form

In 3D printing, powder-based technologies like Selective Laser Sintering (SLS) and Electron Beam Melting (EBM) utilize materials such as metals, plastics, ceramics, and composites. Laser or electron beams fuse powdered materials layer by layer, enabling the creation of intricate objects, particularly in the aerospace, automotive, and healthcare industries.

In contrast, Fused Deposition Modeling (FDM), a popular method, uses filaments, typically made of thermoplastics like PLA, ABS, PETG, and nylon. The filament is heated, extruded through a nozzle, and layered to form objects. FDM is widely adopted for its user-friendly nature, cost-effectiveness, and suitability for rapid prototyping.

Stereolithography (SLA) and Digital Light Processing (DLP) are 3D printing technologies employing liquid resins that solidify when exposed to specific light wavelengths. These resins, available in various types, including standard, flexible, tough, and high-temperature variants, are known for high-resolution printing. SLA and DLP find applications in jewelry making, dentistry, and prototyping, where intricate details are crucial for success.

By Technology

Fused Deposition Modeling/Fused Filament Fabrication (FDM/FFF) is a widely adopted 3D printing technology known for its accessibility, ease of use, and cost-effectiveness. It involves layer-by-layer extrusion of thermoplastic filaments through heated nozzles, making it popular for prototyping, product development, and educational purposes.

Selective Laser Sintering (SLS) utilizes high-powered lasers to sinter powdered materials (plastics, metals, ceramics) layer by layer, creating strong and intricate objects. It finds applications in aerospace, automotive, and medical industries for economically sustainable manufacturing.

Stereolithography (SLA) involves curing liquid photopolymer resin with UV lasers layer by layer, producing highly detailed models. Widely used in jewelry, dental, and product design, SLA is valued for its high resolution and surface finish.

By Application

Rapid prototyping, an early and enduring application of 3D printing, offers a swift and cost-effective method for creating prototypes. Widely used in automotive, aerospace, consumer goods, and electronics industries, it enables designers and engineers to test concepts, iterate designs, and visualize products before mass production.

Moving beyond prototyping, 3D printing has become integral to the actual manufacturing of end-use parts in industries like aerospace, automotive, healthcare, and electronics. Its capability to produce final components with complex geometries, customized designs, and lightweight structures has positioned it as a crucial technology in modern manufacturing processes.

End-Use

In 2023, the aerospace and defense industry claimed a significant 33.4% market share, relying on 3D printing materials to manufacture lightweight yet robust components, driving innovation in manufacturing. The market's growth prospects are fueled by the expanding use of 3D printing in medical applications, particularly for prosthetics, implants, and surgical tools, contributing to the industry's advancement.

In the consumer product and industrial segment, growth is anticipated due to China's manufacturing sector and the increasing use of ceramics in home decor, art, and sculpture. The 3D printing materials market also sees demand from architecture, education, and construction, expected to expand with rising exploration activities and increased adoption in the architectural sector.

Key Market Segments

By Type

- Photopolymers

- Metals

- Plastics

- Other Materials

By Form

- Powder

- Filament

- Liquid

By Technology

- FDM

- SLS

- SLA

- DMLS

- Others

By Application

- Prototyping

- Manufacturing

- Others

End-Use

- Aerospace & Defense Industry

- Automotive Sector

- Medical

- Consumer Products & Industrial Sectors

- Other Applications

Methodology Details Just a Click Away: https://market.us/report/3d-printing-materials-market/request-sample/

Impactful Driver: Technological Advancements

The development of new industrial-grade 3D printing materials is crucial for expanding the technology's potential. Beyond traditional plastics, ceramics, metals, and materials with benefits for the human body now contribute to 3D printing advancements, particularly in areas like electronics and energy production. Innovative filaments, such as the one from The Virtual Foundry, blend PLA with metals like bronze or copper, enabling FDM printers to create intricate and durable objects.

Additionally, the rise of composites, especially in aerospace, further enhances the capabilities of 3D printing, allowing for the production of items with specific properties tailored for critical applications. While ABS and PLA remain common for everyday FDM printers, the introduction of diverse materials is elevating the quality and functionality of 3D-printed objects.

Restraint

The lack of standard process control in 3D printing arises from uncontrollable variables and material disparities across machines and manufacturers. Consistency in each printing process is compromised due to these factors. Currently, few monitoring techniques meet the criteria for reflecting 3D printing process inconsistencies. The limited data available makes it challenging to develop precise mathematical models, particularly in complex applications, leading to output variations influenced by limitations in planning, process control, and pre-and post-production procedures.

Opportunity

The recent surge in 3D printing's popularity can be attributed to the availability of home 3D printers with lower prices, fueling a rapid increase in demand for both these printers and the 3D materials market. Home 3D printers are now ubiquitous, found in homes, offices, computer stores, and shopping malls. They offer users a convenient and cost-effective way to produce low-cost goods quickly, contributing to the widespread adoption of 3D printing technology for personal and small-scale manufacturing purposes.

Challenges

Cost concerns have historically limited the market expansion of 3D printing materials, hindering their adoption in various applications. The challenge for key manufacturers and researchers is to develop low-cost technologies for producing these materials. Currently, the high cost confines the use of 3D printing materials to high-end and luxury cars, creating opportunities for broader applications in the automotive sector as production costs decrease. The consumer and industrial sector is at the forefront of the 3D printing materials market, poised to dominate as the reduced production cost fosters wider utilization.

Regional Analysis

As of 2023, North America held a 32.1% market share in the 3D printing materials market, with predictions of continued expansion driven by increased investments and demand from major players in the region. The growth is facilitated by favorable government policies, a robust manufacturing base, significant research and development investments in high-performance materials, and the widespread availability of 3D printing products.

Anticipated factors for industry growth include rising disposable income and an improved standard of living. Over the forecast period, North America's market is expected to witness increased product demand for metals in industries such as consumer electronics, defense, aerospace, and automotive segments. Additionally, the use of metals, ceramics, and photopolymers in intricate design and manufacturing will contribute to market growth.

In Asia Pacific, the demand for 3D printing materials is expected to rise due to rapid industrialization and infrastructure development, while North America will benefit from increased R&D investments in countries like China, India, Japan, and Indonesia, particularly in upgrading aerospace and defense industry equipment.

By Geography

- North America

- The US

- Canada

- Europe

- Germany

- France

- The UK

- Spain

- Italy

- Russia

- Netherland

- Rest of Europe

- APAC

- China

- Japan

- South Korea

- India

- Australia

- New Zealand

- Singapore

- Thailand

- Vietnam

- Rest of APAC

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- South Africa

- Saudi Arabia

- UAE

- Rest of MEA

Explore Extensive Ongoing Coverage on Chemical Research Reports Domain:

- Protein Ingredients market size is expected to be worth around USD 134.0 billion by 2033, from USD 74.1 billion in 2023, growing at a CAGR of 6.1% during the forecast period from 2023 to 2033.

- Breakfast Cereals market size is expected to be worth around USD 132.7 billion by 2033, from USD 78.6 billion in 2023, growing at a CAGR of 6.0% during the forecast period from 2023 to 2033.

- Gluten-Free Products market size is expected to be worth around USD 18.8 billion by 2033, from USD 8.1 billion in 2023, growing at a CAGR of 8.8% during the forecast period from 2023 to 2033.

- Peanut Butter Market accounted for USD 5.0 billion and will reach USD 8.6 billion by 2032. Between 2023 and 2032, this market is estimated to register a CAGR of 5.6%.

- Herbal Tea market was valued at USD 3.5 billion and is expected to reach USD 6.9 billion in 2032. This market is estimated to register the highest CAGR of 7.2% between 2023 and 2032.

- Cider market size is expected to be worth around USD 29.4 billion by 2033, from USD 17.9 billion in 2023, growing at a CAGR of 5.1% during the forecast period from 2023 to 2033.

- Castor Oil Market was valued at USD 1.4 Billion and is expected to reach USD 2.4 Billion in 2032 from 2023 to 2032, this market is estimated to register a CAGR of 5.8%.

- potato starch market was valued at USD 4.7 billion, and is expected to reach USD 7.5 Billion in 2032 Between 2023 and 2032, this market is estimated to register a CAGR of 4.9%.

- beta-glucan market size is expected to be worth around USD 1040.6 Million by 2033, from USD 495.6 Million in 2023, growing at a CAGR of 7.7% during the forecast period from 2023 to 2033.

- white oil market size is expected to be worth around USD 35.3 billion by 2033, from USD 2.1 billion in 2023, growing at a CAGR of 4.8% during the forecast period from 2023 to 2033.

About Us

Market.US (Powered by Prudour Pvt Ltd) specializes in in-depth market research and analysis and has been proving its mettle as a consulting and customized market research company, apart from being a much sought-after syndicated market research report-providing firm. Market.US provides customization to suit any specific or unique requirement and tailor-makes reports as per request. We go beyond boundaries to take analytics, analysis, study, and outlook to newer heights and broader horizons.

Follow Us On LinkedIn Facebook Twitter

Our Blog: