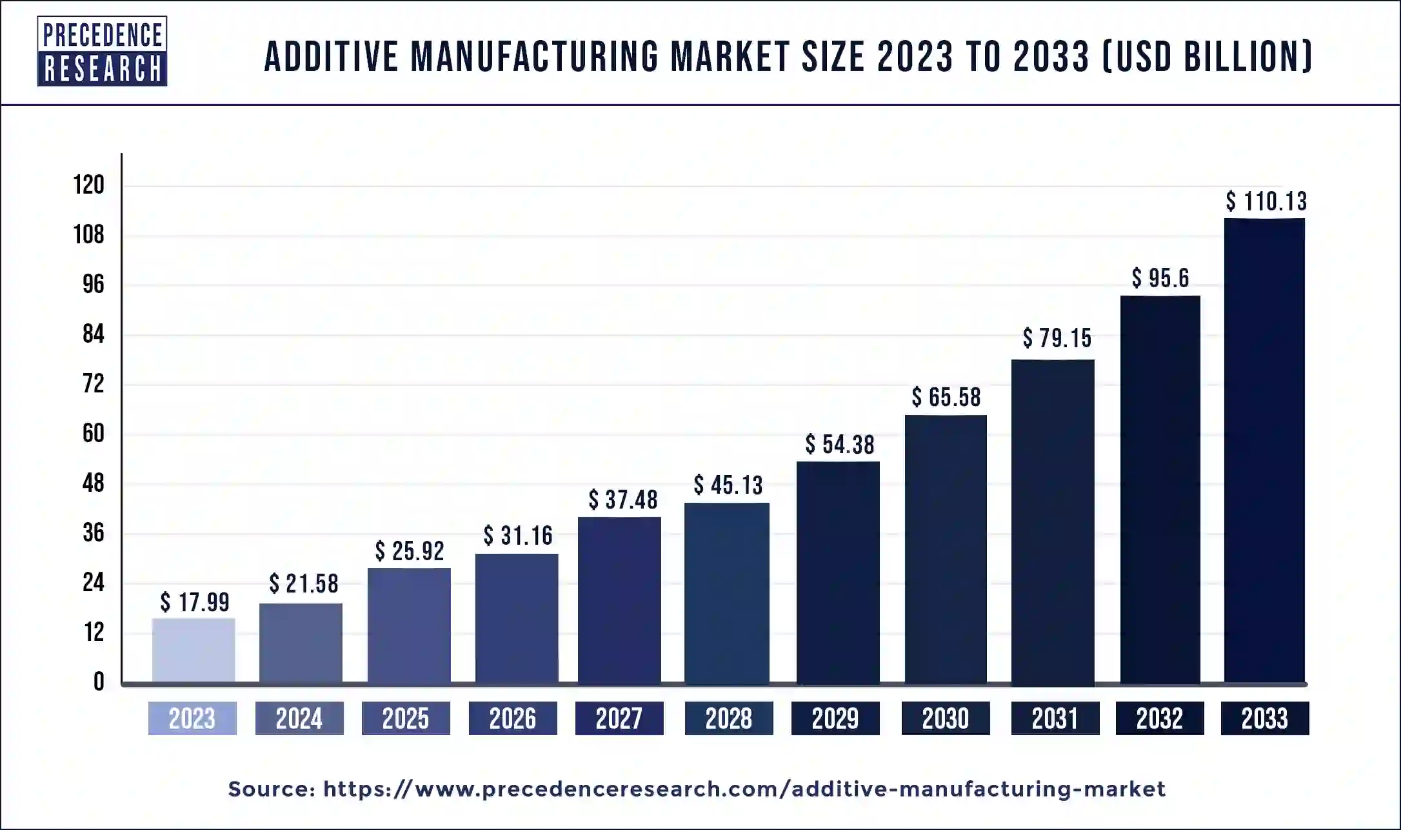

Ottawa, June 07, 2024 (GLOBE NEWSWIRE) -- The global additive manufacturing market size is poised to cross USD 21.58 billion in 2024 and is likely to attain a valuation of USD 110.13 billion by 2033. The additive manufacturing industry is projected to develop at a CAGR of 19.85% from 2024 to 2033.

The additive manufacturing market, commonly known as 3D printing, involves the creation of three-dimensional things using additive techniques and materials such as plastics, metals, and composites. Additive Manufacturing (AM) provides benefits such as 3D printing, quick prototyping, cost savings, and shorter lead times. It enables the fabrication of unique parts with complex geometry while minimizing waste. Materials utilized in AM include metals, biochemicals, thermoplastics, and ceramics.

The Full Study is Readily Available | Download the Sample Pages of this Report@ https://www.precedenceresearch.com/sample/3332

Biochemicals such as calcium phosphate, silicon, and zinc are used in healthcare applications. Ceramics such as alumina, tricalcium phosphate, and zirconia can be mixed with adhesives to produce novel glass goods. Metals like gold, silver, titanium, and stainless steel can be used for various metal components. ABS, PLA, PC, and PVA are thermoplastics that give transient support before breakdown.

Additive Manufacturing Market Key Insights

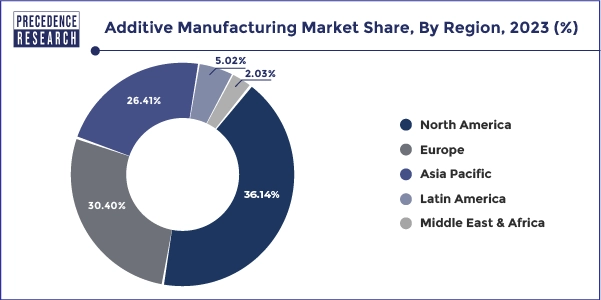

- North America has accounted for the largest market share of 36.14% in 2023.

- Asia Pacific is expected to expand at the fastest CAGR during the forecast period.

- By component type, the hardware segment has held a major market share of 61% in 2023.

- By component type, the software segment is expected to grow at the fastest rate during the forecast period.

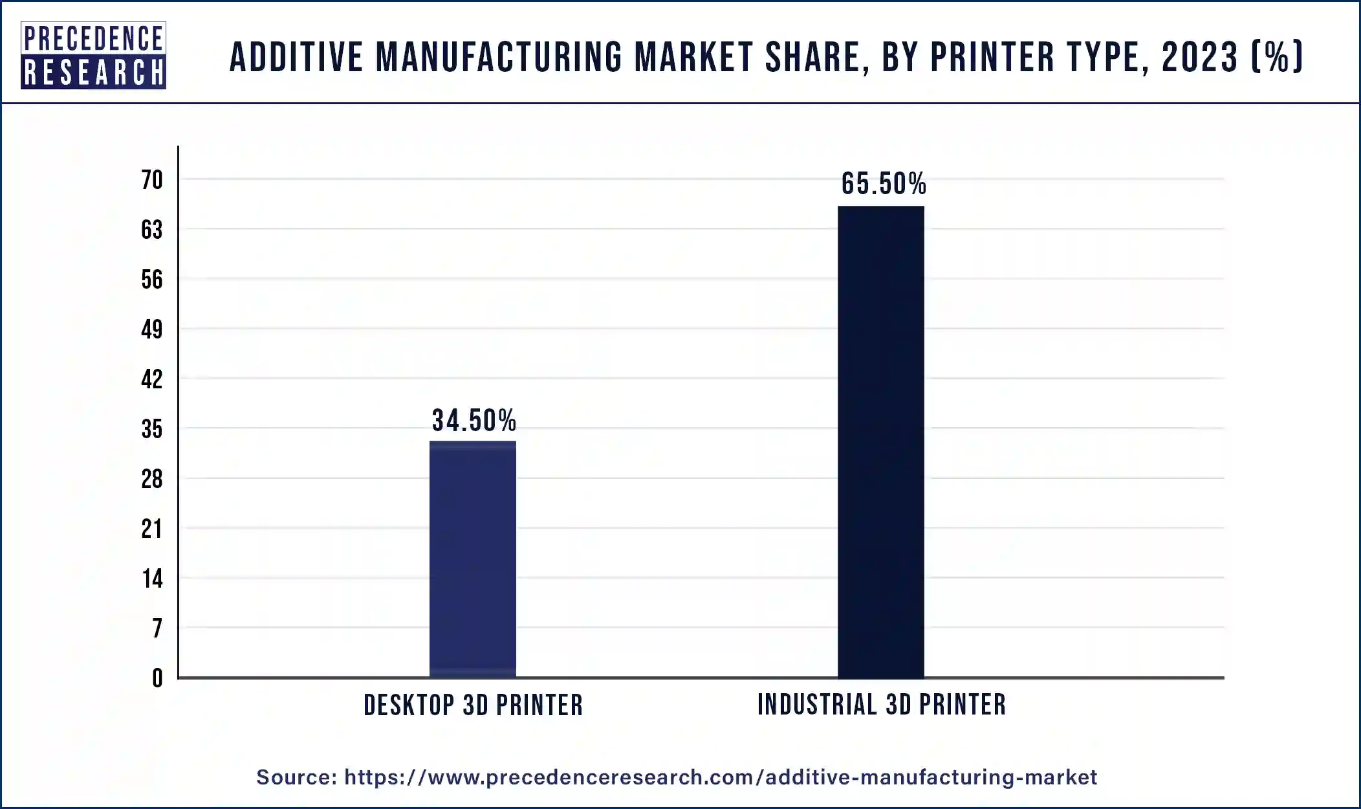

- By printer type, the industrial 3D printer segment has contributed more than 65% market in 2023.

- By printer type, the desktop 3D printer segment is projected to grow at a solid CAGR during the forecast period.

- By technology, the stereolithography segment dominated the market in 2023.

- By software, the design software segment dominated the market in 2023.

- By application, the prototyping segment dominated the market in 2023.

- By vertical, the automotive segment has generated more than 22% of the market share in 2023.

- By Material, the metal segment has held the biggest market share in 2023.

Additive Manufacturing Market Growth Factors

- Attraction of investments and funding into 3D printing companies and startups spurs innovation which is observed to offer a growth factor for the market’s expansion.

- Industries such as defense and aerospace are using 3D printing for lightweight components and complex parts, reducing fuel consumption and improving efficiency. The expansion of end-users in the market is observed to promote the market’s growth.

- The healthcare sector is embracing 3D printing for patient-specific implants, prosthetics, and pharmaceuticals, driving market growth. The ability to quickly prototype and manufacture small batches of products at a lower cost is attractive to various industries, including automotive and aerospace.

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

Additive Manufacturing Market Regional Outlook

North America dominated the additive manufacturing market in 2023. The region's market growth is expected to continue as new technologies become more widely adopted in industries such as military, consumer goods, automotive, aerospace, and healthcare. This expansion of industrial processes increases the usage of 3D printing, ensuring the region's market supremacy.

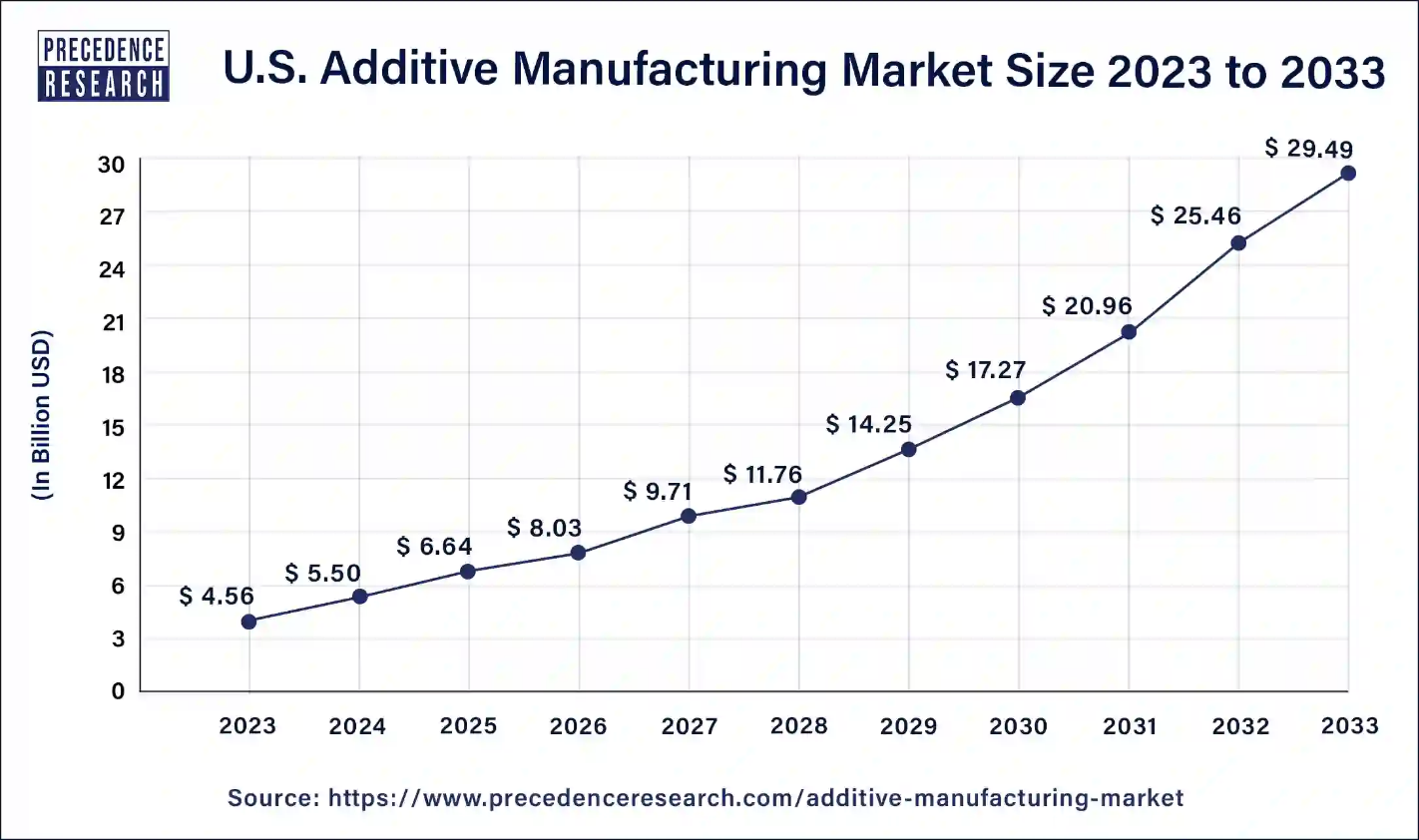

U.S. Additive Manufacturing Market Size and Growth 2024 to 2033

The U.S. additive manufacturing market size accounted for USD 5.50 billion in 2024 and is predicted to surpass around USD 29.49 billion by 2033, expanding at a double-digit CAGR of 20.51% from 2024 to 2033.

The United States has a major proportion of the 3D printing market, owing to its early development and leadership in additive manufacturing. The United States has the most 3D printing firms in the world, including established players like 3D Systems and Stratasys, as well as traditional manufacturing companies such as GE and HP. Furthermore, US-based 3D printing startups attract the largest venture capital funding.

Asia Pacific Additive Manufacturing Market Trends

The Asia Pacific additive manufacturing market is expected to grow at the fastest rate due to expanding industrialization, acceptance of technology, urbanization, and government incentives for sustainable manufacturing processes, all of which are driving the region's additive manufacturing sector growth. China is a leading country in the Asia Pacific region and rules the additive manufacturing industry. India is also leading in the market. There are many startups in India that are doing additive manufacturing, and the companies are also collaborating for growth.

- In April 2024, Indo-MIM, a metal injection molding manufacturer, collaborated with HP on metal 3D part fabrication in India. HP's two metal jet binder 3D printers will be operationalized under the cooperation, allowing for large-scale manufacture of high-precision metal parts for a variety of industries.

Scope of Additive Manufacturing Market

| Report Coverage | Details |

| Additive Manufacturing Market Growth Rate | CAGR of 19.85% from 2024 to 2033 |

| Additive Manufacturing Market Size in 2023 | USD 17.99 Billion |

| Additive Manufacturing Market Size in 2024 | USD 21.58 Billion |

| Additive Manufacturing Market Size by 2033 | USD 110.13 Billion |

| Largest Market | North America |

| Base Year | 2023 |

| Forecast Year | 2024 to 2033 |

| Historical Year | 2021-2022 |

| Segments Covered | Component, Printer Type, Technology, Software, Application, Vertical, Material, and Regions |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa |

Unlock the potential for future growth by requesting your personalized custom report Now! https://www.precedenceresearch.com/customization/3332

Additive Manufacturing Market Report Highlights

Printer Type Outlook

The industrial 3D printer segment dominated the market with the largest revenue share of 65.50% in 2023. Entrepreneurs profit from 3D printing in a variety of ways, including rapid prototyping, customization, risk mitigation, flexibility, sustainability, accessibility to all markets and budgets, quality control possibilities, customer response, pricing, and design independence. It enables speedy and cost-effective prototyping with customizable color, size, and shape options. Quality control guarantees that output satisfies needed quality standards, while customer responsiveness enables organizations to respond to concerns rapidly. While cost may be an issue, the opportunity to recoup investment is great.

The desktop 3D printer segment is expected to grow at a significant rate during the forecast period. Desktop 3D printers are perfect for compact workspaces, particularly for manufacturing enterprises that operate from small factories. They fit on the desk surface, making them a desirable option. 75% of all desktop 3D printers are used for commercial purposes, with only 25% being used for recreational or leisure purposes. Many of them cost less than $1,000, making them more affordable than larger industrial 3D printers. This makes them a popular choice for both businesses and consumers.

Technology Outlook

The stereolithography segment dominated the additive manufacturing market in 2023. Stereolithography (SLA) 3D printing provides precision and intricacy for manufacturing projects. It provides dimensional precision of +/- 0.2%, clean surface finishes, and a wide range of material options. SLA is perfect for developing detailed prototypes that closely resemble the final product.

Maker Verse provides prompt pricing for SLA projects, quick turnaround times, and the capability to handle complex geometries. SLA is also suitable for direct human interaction in the medical field. Its scalability allows it to be used for small to larger production runs while remaining cost-effective for smaller operations.

Software Type Outlook

The design software segment dominated the additive manufacturing market in 2023. Design software provides precision editing, versatility, and scalability. It offers features such as objects, dimensions, and grids to help you work accurately and quickly. It also allows users to undo operations or delete pieces without losing the project.

Design software makes use of vector files, which may be quickly scaled to numerous sizes without sacrificing image quality, allowing for easy replication and use in a variety of mediums.

Application Outlook

The prototyping segment dominated the additive manufacturing market in 2023. Prototyping lowers product development costs, enables functionality testing, removes product failure risk, increases user and stakeholder involvement, and ergonomically examines and detects potential risks. It enables a thorough review of design defects, guaranteeing that the finished product satisfies expectations. Prototyping also fosters teamwork and constructive criticism, resulting in a successful product.

Vertical Outlook

The automotive segment dominated the additive manufacturing market in 2023. Additive manufacturing is a rapidly evolving technology that allows designers to build quick prototypes and complex designs, giving the automotive industry innovative designs, supply chain proficiency, and increased efficiency. BMW recognized this technology 28 years ago, and an Additive Manufacturing Center in Munich produces over 100,000 quality components every year.

Material Outlook

The metal segment dominated the additive manufacturing market in 2023. The rise of the metal material segment is mostly due to its widespread application in additive manufacturing methods in major industries such as automotive and consumer electronics. Metal additive manufacturing techniques employ a wide range of alloys, including stainless steels, tool steels, nickel-base alloys, aluminum, titanium, cobalt chrome alloys, precious metal alloys, and copper alloys. However, heat cycling prevents all metals from being appropriate for AM.

Metal powders for AM are frequently extremely spherical, which influences flowability, surface texture, hardness, cohesiveness, and density. Binder Jetting techniques can be less expensive than alternative AM powders.

Browse More Insights:

- Healthcare Additive Manufacturing Market: The global healthcare additive manufacturing market size was estimated at US$ 2.80 billion in 2022 and is expected to hit around US$ 15.35 billion by 2032, poised to grow at a noteworthy CAGR of 18.60% from 2023 to 2032.

- 3D Bioprinting Market: The global 3D bioprinting market size accounted for USD 2.13 billion in 2022 and is expected to hit around USD 8.3 billion by 2030 and is poised to grow at a CAGR of 18.51% from 2022 to 2030.

- 3D Printing in Healthcare Market: The global 3D printing in healthcare market size was estimated at USD 1.2 billion in 2022 and is expected to hit around USD 6.25 billion by 2032, poised to grow at CAGR of 18% from 2023 to 2032.

- 3D Printing Materials Market: The global 3D printing materials market size is expected to be worth around USD 10.87 billion by 2032 from valued at USD 1.9 billion in 2022 and is expected to grow at a CAGR of 19.1% from 2023 to 2032.

- Digital Printing Market: The global digital printing market size was estimated at USD 26.3 billion in 2022 and is projected to surpass around USD 51.49 billion by 2032, anticipated to grow at a registered CAGR of 7% between 2023 and 2032.

- 3D Imaging Market: The global 3D imaging market size was exhibited at USD 30.28 billion in 2022 and is estimated to surpass around USD 166.01 billion by 2032, expanding at a registered CAGR of 18.6% from 2023 to 2032.

- 3D Printing Medical Implants Market: The global 3D printing medical implants market size was estimated at USD 1.60 billion in 2022 and is predicted to reach USD 8.92 billion by the end of 2032, expanding an impressive CAGR of 19% from 2023 to 2032.

- 3D Metrology Market: The global 3D metrology market size was exceeded at USD 11.84 billion in 2022 and it is expected to hit around USD 22.36 billion by 2032, growing at a CAGR of 6.65% between 2023 and 2032.

- 3D Printing Construction Market: The global 3d printing construction market size was reached at USD 3.42 billion in 2022 and it is projected to hit around USD 519.49 billion by 2032, poised to grow at a CAGR of 65.25% from 2023 to 2032.

- 3D Printed Prosthetics Market: The global 3D printed prosthetics market size was valued at USD 1.54 billion in 2022 and is expected to hit around USD 3.28 billion by 2032, growing at a CAGR of 7.84% from 2023 to 2032.

Additive Manufacturing Market Dynamics

Driver: Simple and fast production

Fast production is a major driver for the additive manufacturing market. Newer 3D printing technologies improve throughput by boosting speed and build volume, minimizing post-processing, and incorporating larger build areas and faster Z-printing. DLP 3D printing technologies involve fewer steps, need less post-processing, and can eliminate or decrease assembly for complicated designs, increasing production efficiency by 50-90%.

Modern additive manufacturing companies prioritize 'production - first' and are developing scalable solutions to simplify and accelerate manufacturing.

Restraint: Workforce shortage

The market requires technical competence to handle and operate AM equipment, which may include both internal development and external training. This long procedure makes it difficult to justify expensive equipment. Labor requirements include more than just file conversion and equipment competence. Depending on the technology, operators may be required to do filament swaps, setting modifications, support structure removal, and post-processing activities.

Opportunity: Automated and Intelligent Software

Advancements in additive manufacturing software, such as generative design, cloud computing, automation, and artificial intelligence, are streamlining manufacturing procedures. These developments close the gap between traditional and additive manufacturing, allowing dental 3D printing to enhance models.

Cloud software optimizes manufacturing capacity among machines, and clients can use on-demand 3D printing machines. In future versions, additive manufacturing software will become more predictive, identifying machines that require maintenance or autonomously modifying printing parameters to ensure consistent production without human intervention.

Recent Developments:

- In April 2024, Linde Advanced Material Technologies Inc., a leading supplier of metal powders in the additive manufacturing industry, and NASA signed a licensing agreement for the GRX-810 Alloy Metal Powder. According to Global Product Manager Sam Assaf, this agreement grants Linde AMT the rights to market and sell the alloy to expand the market potential for aerospace customers.

- In April 2024, INDO-MIM in India used 3D printing to make high-precision metal parts for a variety of sectors, exhibiting additive manufacturing's potential to cut production time and cost. The company demonstrated the use of HP Metal Jet S100 printers.

- In April 2024, ASTM International's F42 additive manufacturing technologies group is working to provide standards for quality assurance and control of materials and components used in additive construction with cement. The standards are intended to increase laboratories, productivity, structural performance, and code regulators, benefiting contractors, structural engineers, and academia.

- In April 2024, Nikon introduced the Lasermeister LM300A metal additive manufacturing machine, which employs Directed Energy Deposition technology, and the Lasermeister SB100 3D scanner. This system is intended for industrial applications and accommodates a larger built area. The LM300A and SB100 are complementary products that add value to the industry, especially for applications such as turbine blades and mold repair.

Additive Manufacturing Market Key Players

- Stratasys, Ltd.

- Autodesk Inc.

- Materialise NV

- GE Additive

- EnvisionTec, Inc.

- Made In Space

- 3D Systems, Inc.

- Voxeljet AG

- Canon Inc.

Market Segmentation

By Component

- Hardware

- Software

- Services

By Printer Type

- Desktop 3D Printer

- Industrial 3D Printer

By Technology

- Stereolithography

- Fused Deposition Modeling

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Polyjet Printing

- Inkjet Printing

- Electron Beam Melting

- Laser Metal Deposition

- Digital Light Processing

- Laminated Object Manufacturing

- Others

By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

By Application

- Prototyping

- Tooling

- Functional Parts

By Vertical

- Industrial Additive Manufacturing

- Automotive

- Aerospace & Defense

- Healthcare

- Consumer Electronics

- Power & Energy

- Others

- Desktop Additive Manufacturing

- Educational Purpose

- Fashion & Jewelry

- Objects

- Dental

- Food

- Others

By Material

- Polymer

- Metal

- Ceramic

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East and Africa

Immediate Delivery Available | Buy This Premium Research Report@ https://www.precedenceresearch.com/checkout/3332

You can place an order or ask any questions, please feel free to contact at sales@precedenceresearch.com | +1 650 460 3308

Unlocking Market Insights through Data Excellence

The "Precedence Statistics" flexible dashboard is a powerful tool that offers real-time news updates, economic and market forecasts, and customizable reports. It can be configured to support a wide range of analysis styles and strategic planning needs. This tool empowers users to stay informed and make data-driven decisions in various scenarios, making it a valuable asset for businesses and professionals looking to stay ahead in today's dynamic and data-driven world.

To Access our Premium Real-Time Data Intelligence Tool, Visit: http://www.precedencestatistics.com

About Us

Precedence Research is a worldwide market research and consulting organization. We give an unmatched nature of offering to our customers present all around the globe across industry verticals. Precedence Research has expertise in giving deep-dive market insight along with market intelligence to our customers spread crosswise over various undertakings. We are obliged to serve our different client base present over the enterprises of medicinal services, healthcare, innovation, next-gen technologies, semi-conductors, chemicals, automotive, and aerospace & defense, among different ventures present globally.

Web: https://www.precedenceresearch.com

Our Blogs:

https://www.towardshealthcare.com

https://www.towardspackaging.com

For Latest Update Follow Us: