United States, Delaware, Nov. 04, 2024 (GLOBE NEWSWIRE) -- The Carbon Mold market is growing due to factors such as the Expanding Applications in Emerging Markets. The carbon mold market is expanding significantly, especially in emerging regions like Asia-Pacific, Latin America, and the Middle East, due to rapid industrialization and growing demand for high-performance products. Key sectors such as automotive, aerospace, and electronics are driving this growth, requiring advanced molding technologies for high-quality components. These regions are investing heavily in manufacturing and infrastructure to boost production capacities and reduce costs, enhancing the appeal of carbon molds.

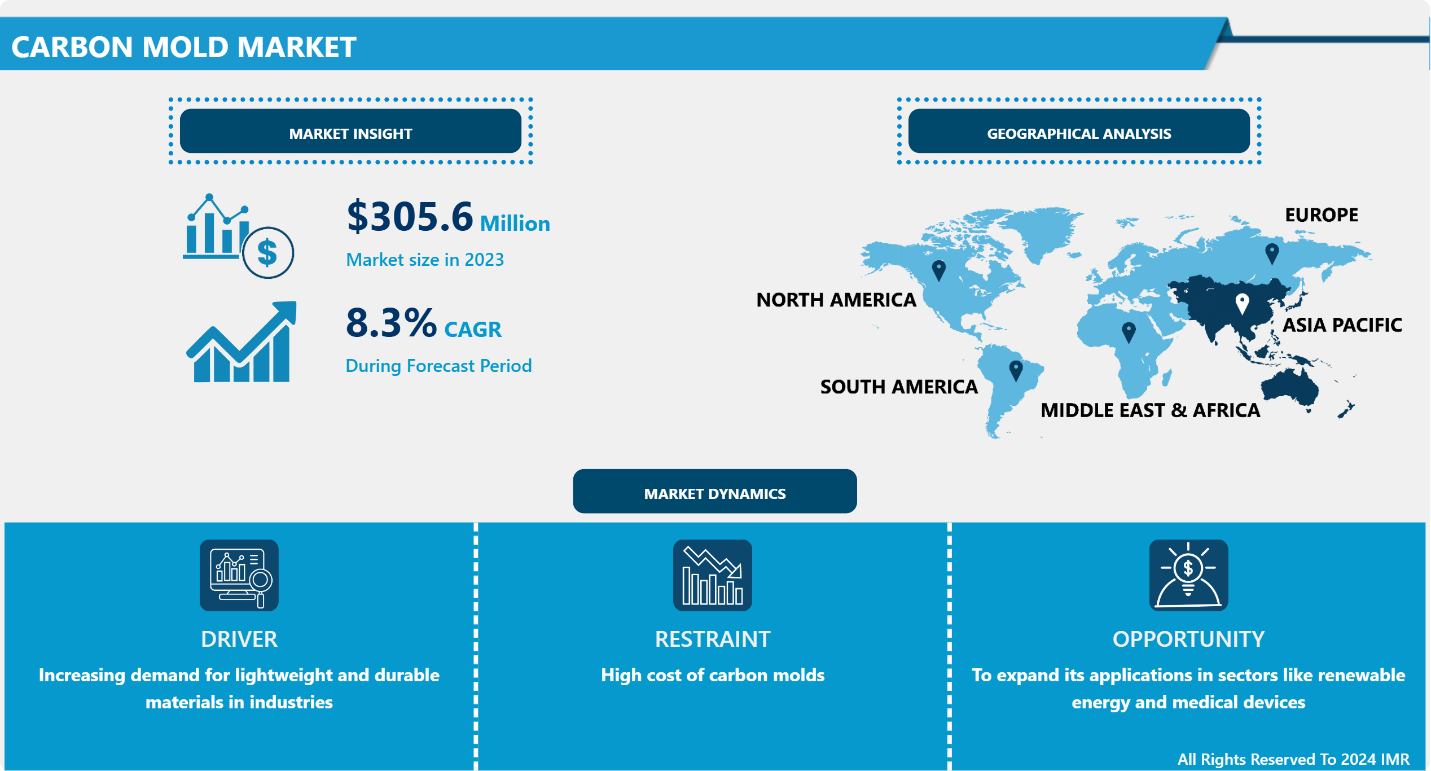

Introspective Market Research is thrilled to announce the release of its newest report, "Carbon Mold Market" This comprehensive analysis reveals that the global Carbon Mold Market, valued at USD 305.6 Million in 2023, is on a trajectory of significant growth, projected to reach USD 626.3 Million by 2032. This upward momentum corresponds to a robust CAGR of 8.3% over the forecast period from 2024 to 2032.

Carbon fiber molding is a sophisticated process used to shape carbon fiber materials into highly durable yet lightweight components. This is achieved by layering carbon fiber sheets within a custom mold, designed to replicate the exact shape and specifications of the final product. Resin is then added, binding the fibers together and creating a solid, structured piece once cured. This approach is favored across industries particularly in automotive, aerospace, and sports manufacturing due to carbon fiber’s unique properties: an outstanding strength-to-weight ratio and impressive durability. These traits make carbon fiber parts ideal for applications where reducing weight is critical, such as in airplanes, racing cars, and sports equipment.

In addition to standard molds, techniques such as filament winding allow carbon fiber to be molded into large, cylindrical structures. This flexibility in design makes it suitable for a range of large-scale applications, from wind turbine blades to structural components in aircraft. The quality and precision of the molds are essential for achieving the desired shape and structural integrity of the final part. High-quality molds, tailored to the product’s unique design and dimensions, ensure accurate replication and adherence to stringent manufacturing standards. Molds made from carbon fiber itself are occasionally used in the industry for their high durability, especially for repeated use in high-stress applications.

Creating carbon fiber molds is a multi-step process that demands expertise in material properties and attention to manufacturing details. Carbon fiber composite materials are processed from their raw form, such as prepreg sheets, through various molding stages until the final part is produced. As carbon fiber technology advances, molding processes continue to evolve, with different methods often coexisting. This allows manufacturers to select the most suitable approach depending on the specific requirements and conditions, achieving optimal results in terms of strength, weight, and longevity for each application.

Download Sample 250 Pages Of Carbon Mold Market Report@ https://introspectivemarketresearch.com/request/17991

Key Industry Insights

Increasing demand for lightweight and durable materials in industries

The carbon mold market is primarily driven by the increasing demand for lightweight and durable materials across industries, particularly in sectors like aerospace, automotive, and marine. Carbon fiber, known for its exceptional strength-to-weight ratio and stiffness, has become a preferred material in these applications. This preference arises from the material's ability to deliver high performance while minimizing weight, which is crucial for fuel efficiency in aerospace and automotive sectors and structural integrity in marine applications.

A critical factor in the efficient use of carbon fiber lies in the precision and quality of molds used in manufacturing processes. Carbon molds allow for accurate shaping and optimal alignment of carbon fibers, resulting in components that maximize the inherent strength and lightweight properties of the material. Carbon molds can withstand the high-temperature processes required to produce carbon fiber components, ensuring durability and reducing production times. With the rise of demand for high-performance materials that do not compromise on weight, the carbon mold market continues to see significant growth across diverse industries, including consumer sporting goods.

Increasing Demand in Automotive and Aerospace

The demand for lightweight and high-strength materials within the automotive and aerospace industries is a major driving factor for the growth of the carbon mold market. Both industries are under increasing pressure to enhance fuel efficiency and reduce emissions due to stringent environmental regulations and shifting consumer preferences towards more sustainable options. Carbon molds, known for their lightweight and durable properties, are essential in producing carbon fiber-reinforced components that meet these requirements.

In the automotive sector, carbon molds facilitate the manufacturing of parts that are significantly lighter than traditional materials like steel or aluminum, which directly improves vehicle performance and fuel efficiency. As electric vehicles (EVs) rise in popularity, manufacturers are increasingly relying on carbon-based materials to extend battery life by reducing vehicle weight. The aerospace industry prioritizes lightweight materials to enhance fuel economy and lower operational costs, making carbon molds indispensable for producing critical aircraft components. This increased adoption of carbon molds, supported by advances in carbon fiber technology and a commitment to sustainability, is expected to drive consistent market growth in the coming years.

"Research made simple and affordable – Trusted Research Tailored just for you – IMR Knowledge Cluster"

https://www.imrknowledgecluster.com/

Technological Advancements in Carbon Fiber Production

The carbon mold market is experiencing significant growth driven by technological advancements in carbon fiber production. Innovations aimed at reducing production costs and improving durability have made carbon fiber an increasingly attractive material across various industries. These advancements support the use of carbon molds, especially in sectors like aerospace, automotive, and sporting goods, where lightweight, durable materials are essential for performance enhancement. With improved manufacturing techniques, such as automation in fiber weaving and innovations in resin transfer molding, the production process has become more efficient and cost-effective. This has enabled manufacturers to produce high-strength carbon fiber at reduced costs, fostering broader adoption of carbon molds.

Enhanced durability achieved through new heat-resistant and impact-resistant fiber formulations ensures that carbon molds meet stringent industry standards, particularly in high-stress environments. These advancements have increased the lifespan and reliability of carbon molds, aligning with sustainability goals by reducing waste and the need for frequent replacements. The carbon mold market benefits from a robust demand driven by technological progress in carbon fiber production, promising continued growth as more industries integrate these innovations.

How can the Carbon Mold Market expand its applications in renewable energy and medical device sectors?

The Carbon Mold Market has strong growth potential in renewable energy, particularly for wind and solar industries. Carbon molds, known for their lightweight and durability, can significantly reduce the weight of turbine blades, allowing for larger, more efficient wind turbines. The demand for carbon molds in this sector is likely to increase in tandem. The solar sector’s use of carbon molds for lightweight, high-strength frames supports the development of more portable, durable solar panel structures, enhancing both efficiency and adaptability across various terrains.

In the medical device sector, carbon molds offer unique advantages in producing precision tools and lightweight prosthetics, where strength, durability, and flexibility are critical. This market segment is expanding with the increasing adoption of carbon composite materials that provide both patient comfort and performance. The demand for lightweight, durable materials like carbon molds is positioned to grow, particularly for advanced surgical equipment and implantable devices that require high accuracy and customizability.

How can the Carbon Mold Market address the challenge of high production costs in molds?

The Carbon Mold Market faces a significant challenge due to high production costs, primarily driven by the expenses associated with raw materials, advanced processing, and energy-intensive manufacturing techniques. Labor costs for highly skilled technicians required in precision molding processes further escalate expenses. These costs make carbon molds a less accessible option, particularly for smaller manufacturers aiming to adopt lightweight and durable materials in production.

Despite these cost barriers, the demand for carbon molds continues to grow, especially in the automotive and aerospace industries, where lightweight and high-strength properties are critical. To tackle these challenges, companies in the market are focusing on innovative manufacturing processes, such as automated fiber placement (AFP) and out-of-autoclave (OOA) techniques, to reduce labor and energy costs.

Do you need any industry insights on Carbon Mold Market, Make an enquiry now >> https://introspectivemarketresearch.com/inquiry/17991

Key Manufacturers

Market key players and organizations within a specific industry or market that significantly influence its dynamics. Identifying these key players is essential for understanding competitive positioning, market trends, and strategic opportunities.

- Asbury Carbons (USA)

- Carbone Lorraine (France)

- GrafTech International (USA)

- Graphite India Limited (India)

- IBIDEN Co., Ltd. (Japan)

- Imerys Graphite & Carbon (Switzerland)

- Mersen (France)

- Morgan Advanced Materials (UK)

- Nippon Carbon Co., Ltd. (Japan)

- Poco Graphite (USA)

- Schunk Group (Germany)

- SEC Carbon, Ltd. (Japan)

- SGL Carbon (Germany)

- Tokai Carbon (Japan)

- Toyo Tanso (Japan), Other Key Players.

Recent Industry Development

In January 2024, Asbury Carbons Inc. announced price increases of up to 10% on its graphite, cokes, and non-carbon products, to offset rising costs in raw materials, energy, and transportation. Established in 1895 and headquartered in Asbury, NJ, Asbury Carbons supplies over 2,000 grades of materials for diverse industries and operates 12 manufacturing sites worldwide.

In May 2023, Graphite India is acquiring a 31% stake in Godi India for ₹50 crores through compulsorily convertible preference shares, enhancing its diversification into advanced battery and energy storage systems. This investment supports Graphite India’s strategy in sustainable energy, with Godi India focusing on advanced chemistry for EV batteries and supercapacitor-based energy storage.

Key Segment of Market Report:

By Material Type

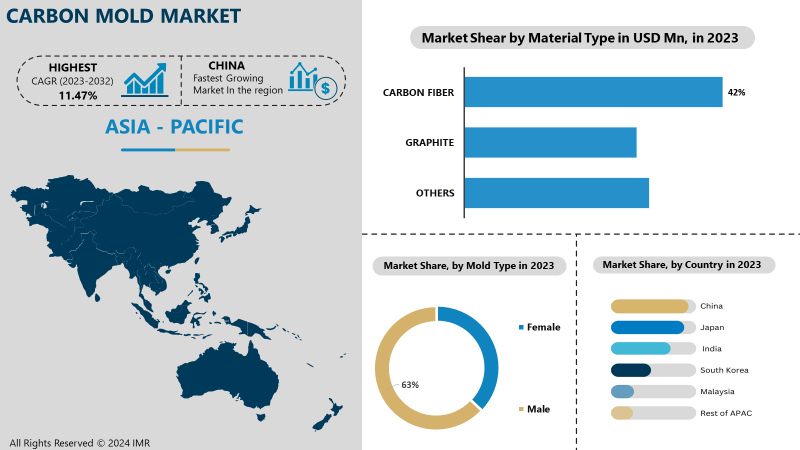

The carbon fiber segment is projected to lead the carbon mold market during the forecast period, owing to its high strength-to-weight ratio, durability, and heat resistance. Carbon fiber molds are increasingly essential in aerospace, automotive, and renewable energy sectors, where lightweight materials enhance fuel efficiency and performance. In aerospace, carbon fiber molds are used to manufacture aircraft wings, fuselage sections, and structural components, reducing overall weight and improving safety and efficiency. The automotive sector similarly relies on carbon fiber molds to produce lighter parts, which contribute to better fuel economy and reduced emissions. In the renewable energy industry, especially wind energy, carbon fiber molds support the creation of large, complex structures, such as turbine blades, which require materials that can withstand extensive stress and harsh environmental conditions.

Given its performance advantages, the carbon fiber segment is expected to maintain dominance as industries prioritize efficiency and sustainability. With growing applications and demand in these sectors, carbon fiber molds are likely to see substantial growth, driven by their capacity to meet stringent requirements for durability, weight reduction, and overall operational performance in a wide range of applications.

By Mold Type

The male mold segment is anticipated to dominate the carbon mold market throughout the forecast period. This preference arises because male molds are ideal for applications requiring precise external contouring and detailing. Male molds, where the material is formed outside the mold, are widely used in industries such as aerospace, automotive, and construction due to their capability to create complex shapes with thin walls and a high-quality surface finish. In aerospace, male molds are essential for producing thin-sheet metal components like aircraft skin panels and wings, which demand tight tolerances for optimal performance.

In the automotive sector, male molds are similarly favored for manufacturing body panels and exterior parts, where accuracy and smooth finishes are critical. Male molds also offer cost and efficiency advantages by requiring less material than female molds to form a structure, resulting in lighter yet robust components. These attributes of precision, lightweight, and efficient material usage have established male molds as the leading segment in terms of market share across various industries. Their strengths make them particularly suitable for high-strength, accurately shaped casting, further reinforcing their dominance in the carbon mold market.

If you require any specific information that is not covered currently, we will provide the same as a part of the customization >> https://introspectivemarketresearch.com/custom-research/17991

By Region:

The Asia-Pacific region became the largest contributor to the carbon composites market, driven by advancements in the automotive, aerospace, and electronics sectors, which heavily rely on high-strength, lightweight materials for fuel-efficient designs. This growth is led by countries like China, Japan, and South Korea, which are central players in carbon mold production due to their advanced manufacturing and industrial capabilities. Automotive manufacturers in the region benefit from the use of carbon composites to produce lighter, fuel-efficient vehicles, in line with increasing environmental regulations and the rise of electric vehicles. In electronics, demand for carbon molds continues to grow, particularly in semiconductor and microchip production, enhancing precision and durability in these critical components.

The Asia-Pacific region accounts for an estimated 40% of the global market share in carbon composites, bolstered by investments in research and development aimed at enhancing material longevity and performance. This regional dominance is expected to persist as technological improvements and automated production techniques become more integrated, keeping Asia-Pacific at the forefront of the carbon mold market. This sector, currently valued at approximately USD 25 billion globally, is projected to grow significantly, supported by ongoing innovation in material.

Comprehensive Offerings:

- Historical Market Size and Competitive Analysis (2017–2023): Detailed assessment of market size and competitive landscape over the past years.

- Historical Pricing Trends and Regional Price Curve (2017–2023): Analysis of historical pricing data and price trends across different regions.

- Market Size, Share, and Forecast by Segment (2024–2032): Projections and detailed insights into market size, share, and future growth by segment.

- Market Dynamics: In-depth analysis of growth drivers, restraints, opportunities, and key trends, with a focus on regional variations.

- Market Trend Analysis: Evaluation of emerging trends that are shaping the market landscape.

- Import and Export Analysis: Examination of trade patterns and their impact on market dynamics.

- Market Segmentation: Comprehensive analysis of market segments and sub-segments, with a regional breakdown.

- Competitive Landscape: Strategic profiles of key players across regions, including competitive benchmarking.

- PESTLE Analysis: Evaluation of the market through Political, Economic, Social, Technological, Legal, and Environmental factors.

- PORTER’s Five Forces Analysis: Assessment of competitive forces influencing the market.

- Industry Value Chain Analysis: Examination of the value chain to identify key stages and contributors.

- Legal and Regulatory Environment by Region: Analysis of the legal landscape and its implications for business operations.

- Strategic Opportunities and SWOT Analysis: Identification of lucrative business opportunities, coupled with a SWOT analysis.

- Conclusion and Strategic Recommendations: Final insights and actionable recommendations for stakeholders.

Related Report Links:

Ocean-Based Carbon Dioxide Removal Market: Ocean-Based Carbon Dioxide Removal Market Size Was Valued at USD 545.37 Million in 2023 and is Projected to Reach USD 2129.38 Million by 2032, Growing at a CAGR of 16.34 % From 2023-2032.

Carbon Fibre Tape Market: Carbon Fibre Tape Market Size is Valued at USD 2.4 Billion in 2023, and is Projected to Reach USD 4.8 Billion by 2032, Growing at a CAGR of 8.6% From 2024-2032.

Carbon Dioxide (CO2) Monitors Market: Carbon Dioxide (CO2) Monitors Market Size is Valued at USD 0.46741 Billion in 2023, and is Projected to Reach USD 0.84 Billion by 2032, Growing at a CAGR of 7.60% From 2024-2032.

Renewable Carbon Fibers Market: Renewable Carbon Fibers Market Size Was Valued at USD 73 Billion in 2023 and is Projected to Reach USD 103.63 Billion by 2032, Growing at a CAGR of 3.97% From 2024-2032

Carbon Nanotubes Market: Carbon Nanotubes Market Size Was Valued at USD 1.10 Billion in 2023, and is Projected to Reach USD 4.06 Billion by 2032, Growing at a CAGR of 15.60% From 2024-2032.

Recycled Carbon Products Market: Recycled Carbon Products Market Size Was Valued at USD 144.56 Million in 2023, and is Projected to Reach USD 380.19 Million by 2032, Growing at a CAGR of 11.39% From 2024-2032.

Sodium Carbonate Market: Sodium Carbonate Market Size Was Valued at USD 13.5 Billion in 2023, and is Projected to Reach USD 23.2 Billion by 2032, Growing at a CAGR of 6.2% From 2024-2032

Carbon Fiber Market: Carbon Fiber Market Size Was Valued at USD 3.2 Billion in 2023, and is Projected to Reach USD 6.0 Billion by 2032, Growing at a CAGR of 7.2% From 2024-2032.

Dimethyl Carbonate Market: Dimethyl Carbonate Market Size is Valued at USD 1.23 Billion in 2023, and is Projected to Reach USD 3.22 Billion by 2032, Growing at a CAGR of 12.70% From 2024-2032.

Carbon Wheels Market: Carbon Wheels Market Size Was Valued at USD 800 Million in 2023 and is Projected to Reach USD 2074.99 Million by 2032, Growing at a CAGR of 10 % From 2024-2032.

About Us:

Introspective Market Research is a premier global market research firm, leveraging big data and advanced analytics to provide strategic insights and consulting solutions that empower clients to anticipate future market dynamics. Our team of experts at IMR enables businesses to gain a comprehensive understanding of historical and current market trends, offering a clear vision for future developments.

Our strong professional network with industry-leading companies grants us access to critical market data, ensuring the generation of precise research data tables and the highest level of accuracy in market forecasting. Under the leadership of CEO Mrs. Swati Kalagate, who fosters a culture of excellence, we are committed to delivering high-quality data and supporting our clients in achieving their business goals.

The insights in our reports are derived from primary interviews with key executives of top companies in the relevant sectors. Our robust secondary data collection process includes extensive online and offline research, coupled with in-depth discussions with knowledgeable industry professionals and analysts.

Contact Us:

Canada Office

Introspective Market Research Private Limited, 138 Downes Street Unit 6203- M5E 0E4, Toronto, Canada.

APAC Office

Introspective Market Research Private Limited, Office No. 401, Saudamini Commercial Complex, Kothrud, Pune, India 411038

Ph no: +91-81800-96367 / +91-7410103736

Email: sales@introspectivemarketresearch.com

LinkedIn| Twitter| Facebook | Instagram

Ours Websites : https://introspectivemarketresearch.com | https://imrknowledgecluster.com/knowledge-cluster | https://imrtechsolutions.com | https://imrnewswire.com/ | https://marketnresearch.de |