Australia, Sydney, Nov. 06, 2024 (GLOBE NEWSWIRE) -- An upward trend in the Industrial coatings Market sector is the rising popularity of self-cleaning hydrophobic coatings. These coatings, created to repel water by causing it to form beads, efficiently direct moisture to certain areas, stopping it from spreading on surfaces. Therefore, they have a crucial role in reducing corrosion and upkeeping surface cleanliness. This shift is motivated by an increased emphasis on long-lasting, environmentally-friendly alternatives, and the demand for effective, easy-to-care-for options in building, transportation, and products for the general public. With the ongoing progress in nanotechnology and surface engineering, self-cleaning coatings are projected to infiltrate additional industries, providing enhanced defense and increased durability on various materials.

Introspective Market Research is thrilled to announce the release of its newest report, "Industrial Coatings Market." This comprehensive analysis reveals that the global Industrial Coatings market, valued at USD 150.12 Billion in 2023, is on a trajectory of significant growth, projected to reach USD 215.52 Billion by 2032. This upward momentum corresponds to a robust CAGR of 4.1% over the forecast period from 2024 to 2032.

Industrial coatings are beneficial as they offer vital protection for various surfaces and industries. One key advantage is the shield from rust, flames, and contact with chemicals. Epoxy coatings are frequently applied in chemical processing facilities to endure spills, whereas zinc-rich coatings offer corrosion protection for steel structures. This protection guarantees that surfaces stay undamaged, even in tough conditions, reducing harm and prolonging their durability.

Another important advantage of industrial coatings is their long-lasting quality. These coatings improve surface durability, enabling equipment and infrastructure to resist damage and deterioration. Industries such as manufacturing and mining save time and money by decreasing the frequency of maintenance and replacements. Coatings are necessary for managing assets over the long term due to their durability. Industrial coatings not only provide protection and durability but also enhance workplace safety. Coatings containing anti-slip features can reduce the chance of accidents by preventing slips in places where floors could get wet or oily. This characteristic is particularly crucial in settings such as food processing facilities or factories that prioritize safety.

Industrial coatings also offer protection from harsh weather elements like rain, wind, ice, and UV radiation, ensuring surfaces remain resilient. This resilience makes coatings perfect for outdoor structures and equipment that are exposed to the elements, guaranteeing they stay operational and structurally stable. Furthermore, using industrial coatings helps to reduce costs by reducing the necessity for costly repairs and replacements. Some coatings that are environmentally friendly also skip the use of harmful chemicals, which helps support sustainability. Some coatings, such as powder coatings, only need to be applied once, which makes them efficient and cost-effective for big operations. Protecting equipment and structures from corrosion and damage in environments with moisture, chemicals, and harsh conditions is critical, making industrial coatings essential. Their main purpose is to protect substances.

Download Sample 250 Pages Of Industrial Coatings Market Report@ https://introspectivemarketresearch.com/request/17095

Key Industry Insights

1. Growth in Manufacturing Sector

The expansion of the manufacturing sector significantly drives the industrial coatings market. As industries such as automotive, aerospace, and machinery increase production capacity, the demand for high-performance coatings to protect equipment and enhance aesthetics rises. Coatings not only provide corrosion resistance and durability but also improve the appearance of products, making them more appealing to consumers. The shift towards advanced manufacturing techniques and materials also necessitates the use of specialized coatings that can withstand harsh operating conditions.

2. Increased Focus on Sustainability

There is a growing emphasis on sustainability and environmental protection within the industrial coatings market. Manufacturers are increasingly seeking eco-friendly formulations, such as water-based coatings and low-VOC (volatile organic compounds) options, to reduce their environmental impact. Regulatory requirements and consumer preferences for greener products are encouraging companies to invest in sustainable technologies and practices. This shift not only meets compliance standards but also positions companies as responsible entities, attracting environmentally conscious consumers and partners.

3. Technological Advancements

Technological innovation plays a pivotal role in the industrial coatings market. Developments in coating formulations, application techniques, and curing processes enhance the performance and efficiency of coatings. For instance, advancements in nano-coatings offer superior protection and durability while reducing application costs. The rise of smart coatings that can change properties based on environmental conditions is also gaining traction, providing additional functionality for end-users. These innovations drive demand as industries seek to improve product lifespan and performance while optimizing costs.

4. Infrastructure Development

Infrastructure development, particularly in emerging economies, significantly impacts the industrial coatings market. Governments are investing in various infrastructure projects, including transportation, energy, and construction, which necessitate high-quality coatings for protection and aesthetics. The growth of urbanization and population leads to increased demand for housing, roads, and public facilities, all requiring durable and protective coatings. Additionally, the maintenance and refurbishment of existing infrastructure contribute to the ongoing need for industrial coatings, further driving market growth.

"Research made simple and affordable – Trusted Research Tailored just for you – IMR Knowledge Cluster"

https://www.imrknowledgecluster.com/

How can industrial coatings manufacturers leverage the demand for sustainable coatings to boost competitiveness and drive innovation?

A big opportunity in the industrial coatings market is the move towards sustainability and environmentally friendly products. Due to the increasing global awareness of environmental concerns, both consumers and businesses are now looking for coatings that reduce their environmental footprint. The trend is being caused by tighter regulations on VOC emissions and hazardous substances, forcing manufacturers to create environmentally friendly alternatives. Environmentally friendly coatings, like water-based and powder coatings, are becoming more popular due to their lower emissions of harmful chemicals in comparison to traditional solvent-based options. These coatings not only comply with regulations but also attract environmentally aware customers, giving a competitive edge.

Furthermore, in a competitive market, companies can distinguish themselves by investing in research and development to produce long-lasting, eco-friendly coatings. This chance can be found in a range of industries such as automotive, construction, and consumer goods, all of which require coatings that are efficient and eco-friendly. By adopting this sustainability trend, producers are able to access an expanding clientele and also make a positive impact on environmental preservation. This strategic emphasis not only boosts brand image but also creates opportunities for forming alliances and partnerships with sustainable-minded organizations, promoting lasting growth in the industrial coatings industry.

How can industrial coatings manufacturers ensure regulatory compliance with VOCs and HAPs?

Regulatory compliance presents a major obstacle in the industrial coatings industry. With increasing environmental consciousness, governments around the world are enforcing more stringent rules on the utilization of volatile organic compounds (VOCs) and hazardous air pollutants (HAPs) in coating formulas. These rules are designed to decrease air pollution and safeguard public health, forcing manufacturers to change the composition of their products.

The difficulty extends beyond following current rules to also include predicting and adjusting to upcoming modifications. Meeting compliance standards usually involves making a significant investment in research and development to develop safer, environmentally friendly alternatives that also meet performance criteria. Furthermore, manufacturers are required to ensure that their production methods comply with regulatory standards, which may require upgrading machinery and providing staff with training.

Additionally, the expense of meeting regulations can reduce profit margins, especially for smaller companies that may not have the funds to make required adjustments. It is important to navigate the intricate regulatory environment in order to stay competitive and prioritize product safety and environmental responsibility. Continuous monitoring of regulatory changes and proactive adjustments to product lines are crucial for achieving long-term success in the industrial coatings market.

Do you need any industry insights on Industrial Coatings Market, Make an enquiry now >>? https://introspectivemarketresearch.com/inquiry/17095

Key Manufacturers

Recognize the key individuals and entities in a specific ndustry or market that significantly influence its operations. Identifying these key individuals is essential for understanding competitive positioning, market trends, and strategic opportunities.

- AkzoNobel N.V. (Netherlands)

- Ppg Industries, Inc. (Usa)

- Sherwin-Williams Company (Usa)

- Axalta Coating Systems Ltd. (Usa)

- Basf Se (Germany)

- Rpm International Inc. (Usa)

- Nippon Paint Holdings Co., Ltd. (Japan)

- Jotun Group (Norway)

- Kansai Paint Co., Ltd. (Japan)

- Asian Paints Ltd. (India)

- Tikkurila Oyj (Finland)

- Hempel A/S (Denmark)

- Valspar Corporation (Now Part Of Sherwin-Williams) (Usa)

- Beckers Group (Sweden)

- Berger Paints India Ltd. (India)

- Masco Corporation (Usa)

- Sika Ag (Switzerland)

- Rpm International Inc. (Usa)

- 3m Company (Usa)

- Henkel Ag & Co. Kgaa (Germany)

- Teknos Group Oy (Finland)

- Carpoly Chemical Group Co., Ltd. (China)

- Benjamin Moore & Co. (Usa)

- Valspar Corporation (Part of Sherwin-Williams) (Usa)

- Ashland Inc. (Usa) and Other Active Members

In October 2024, American Industrial Partners (AIP), an industrials investor, announced that it had entered into a definitive agreement to acquire PPG's architectural coatings business in the United States and Canada. This acquisition was facilitated by American Industrial Partners Capital Fund VIII. PPG, a global leader in paints, coatings, and specialty materials, was set to finalize the transaction by late 2024 or early 2025, pending customary closing conditions. This strategic move aimed to enhance AIP's portfolio in the coatings sector, reflecting the firm’s commitment to investing in industrial businesses. The deal marked a significant milestone in both companies' operations.

In September 2024, Crawford United Corporation announced the acquisition of Advanced Industrial Coatings based in Stockton, California, effective August 30, 2024. Advanced Industrial Coatings specialized in providing solutions across various sectors, including aerospace, semiconductor, medical, and energy. The company met the demanding requirements for fluoropolymers and other high-performance coatings by offering custom solutions that included non-stick, heat-resistant, chemical-resistant, and anti-corrosion applications. This acquisition aimed to enhance Crawford United's portfolio and capabilities in delivering specialized coating solutions to address the complex needs of its diverse clientele in the industrial market.

In February 2024, BASF Coatings signed a Global Preferred Partnership agreement with INEOS Automotive regarding its Global Body and Paint Program. The two companies established a long-term strategic collaboration aimed at exceeding industry standards in vehicle body repair and paint refinishing. This partnership included the supply of sustainable refinish solutions, along with expertise in the latest digital color-matching technologies and comprehensive training. Through this agreement, BASF and INEOS Automotive aimed to enhance the quality and sustainability of automotive refinishing, reflecting a commitment to innovation and excellence in the automotive industry.

Key Segments of Market Report

By Product:

Epoxy coatings have emerged as a leading choice in the mechanical coatings market due to their exceptional performance characteristics and versatility. These coatings are highly valued for their superior protective properties, offering strong resistance to corrosion, abrasion, and chemical exposure. This makes them particularly suitable for demanding environments such as marine, oil and gas, automotive, and aerospace industries, where surfaces are constantly subjected to harsh conditions. Epoxy coatings can be tailored to meet specific application requirements, providing features like high thermal resistance, flexibility, and conductivity. Their strong adhesion and durability allow them to bond effectively to various substrates, including metals, concrete, and wood, ensuring long-lasting protection, especially in areas where maintenance is limited or costly.

The ease of application, with methods such as spraying, rolling, and brushing, combined with rapid curing times, makes epoxy coatings practical for a range of industries, minimizing project downtime. Additionally, they enhance both the aesthetics and functionality of surfaces, available in various colors and finishes and offering special properties like non-slip or anti-static features. While other coatings like acrylic and polyurethane have their niches, the unique blend of protective, durable, and aesthetic qualities secures epoxy coatings' dominant position in the market.

By Technology:

The Water Borne segment of the mechanical coatings market was primarily dominated by waterborne coatings, which have gained prominence due to their environmental benefits. Waterborne coatings utilize water as the primary solvent, significantly reducing the emission of volatile organic compounds (VOCs), which are harmful pollutants contributing to air quality degradation and health risks. This eco-friendly characteristic makes waterborne coatings highly attractive for manufacturers and industries striving to comply with increasingly stringent environmental regulations globally.

Governments and regulatory bodies have implemented these rules to combat air pollution, and the lower VOC emissions of waterborne coatings facilitate easier compliance while reducing the environmental footprint of industrial processes. In addition to their environmental advantages, waterborne coatings provide substantial health and safety benefits. They are generally safer to handle and apply compared to solvent-borne coatings, which often contain flammable and toxic chemicals. The use of water as a solvent minimizes combustibility and exposure to hazardous vapors, thereby creating a safer working environment for workers.

Technological advancements have further enhanced the performance characteristics of waterborne coatings, making them competitive with or even superior to traditional solvent-borne options. Modern formulations now offer exceptional durability, adhesion, corrosion resistance, and aesthetic quality, making them suitable across various industries, including automotive, aerospace, marine, and industrial manufacturing. As sustainability continues to be a priority for both businesses and consumers, the adoption of waterborne coatings is expected to grow, ensuring their ongoing dominance and development in the mechanical coatings market.

By Region:

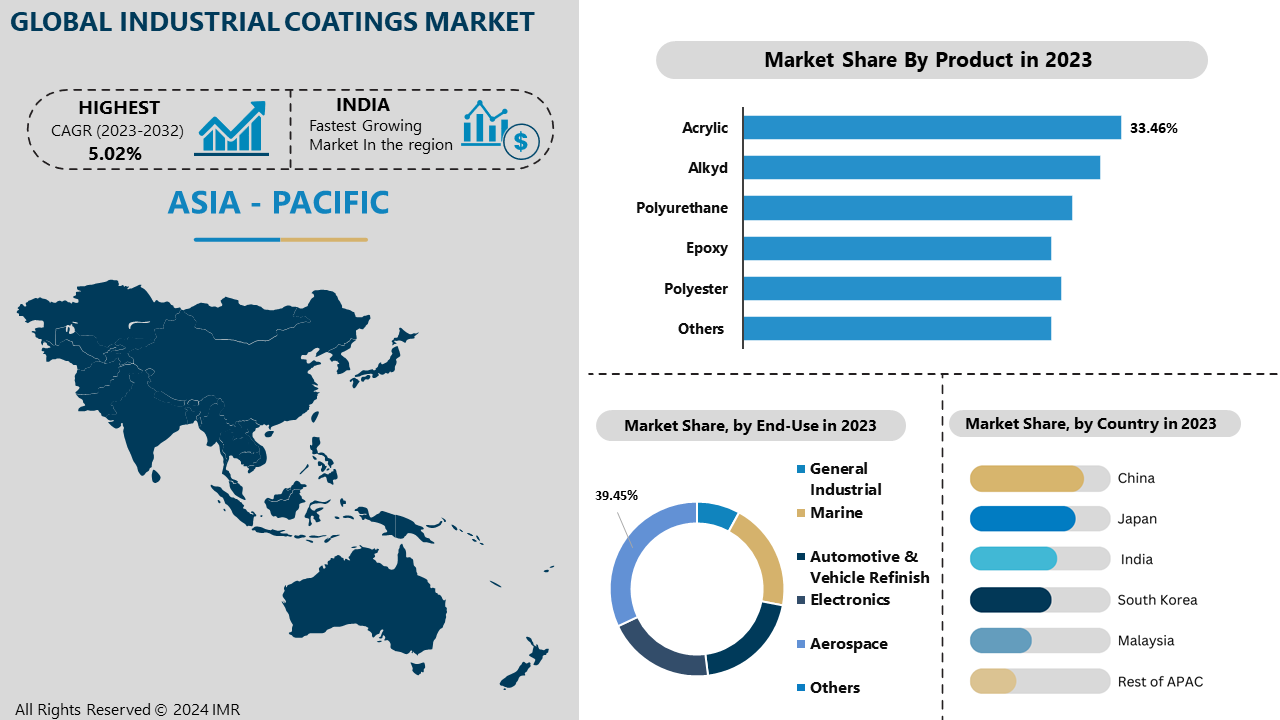

The Asia Pacific dominates the global industrial coatings market, largely due to rapid industrialization and urbanization in major economies such as China, India, Japan, and South Korea. This growth is fueled by robust demand from key sectors including automotive, construction, marine, and electronics. China’s extensive manufacturing base and significant infrastructure projects, along with India’s expanding industrial sector, are pivotal in driving this demand.

The region is home to numerous local and international manufacturers, providing a diverse array of products and innovations tailored to meet various industrial needs. The relatively lower labor and production costs, along with favorable government policies in certain countries, further strengthen the market. Additionally, the burgeoning automotive industry and increased investments in infrastructure and construction projects contribute significantly to demand.

Advancements in coating technologies and a growing emphasis on sustainable and eco-friendly solutions align with global environmental trends, promoting market growth. The combination of these factors positions the Asia-Pacific region as a critical hub for industrial coatings, ensuring continued expansion and innovation in response to evolving industrial requirements and sustainability goals.

If you require any specific information that is not covered currently, we will provide the same as a part of the customization >> https://introspectivemarketresearch.com/custom-research/17095

Comprehensive Offerings:

- Historical Market Size and Competitive Landscape (2017–2023): A comprehensive evaluation of market size and the competitive environment over the recent years.

- Historical Pricing Trends and Regional Price Analysis (2017–2023): A review of past pricing data and trends across various regions.

- Market Size, Share, and Forecast by Segment (2024–2032): Predictions and detailed insights into market size, share, and anticipated growth by segment.

- Market Dynamics: An extensive analysis of growth factors, constraints, opportunities, and significant trends, with a focus on regional differences.

- Market Trend Analysis: Assessment of emerging trends that are influencing the market landscape.

- Import and Export Overview: Analysis of trade patterns and their effects on market dynamics.

- Market Segmentation: A thorough examination of market segments and sub-segments, along with a regional breakdown.

- Competitive Landscape: Strategic profiles of major players in different regions, including competitive benchmarking.

- PESTLE Analysis: An evaluation of the market based on Political, Economic, Social, Technological, Legal, and Environmental factors.

- PORTER’s Five Forces Analysis: An analysis of the competitive forces that impact the market.

- Industry Value Chain Examination: A look into the value chain to identify key stages and contributors.

- Legal and Regulatory Framework by Region: An analysis of the legal environment and its implications for business operations.

- Strategic Opportunities and SWOT Analysis: Identification of profitable business opportunities, along with a SWOT analysis.

- Conclusion and Strategic Recommendations: Final insights and actionable suggestions for stakeholders.

Related Report Links:

Paint Thinners Market: Paint Thinners Market Size Was Valued at USD 21.36 Billion in 2023, and is Projected to Reach USD 37.02 Billion by 2032, Growing at a CAGR of 6.3% From 2024-2032.

Silicone-based Release Coatings Market: Silicone-based Release Coatings Market Size is Valued at USD 8.062 Billion in 2023, and is Projected to Reach USD 13.74 Billion by 2032, Growing at a CAGR of 6.90% From 2024-2032.

Polyurea Coatings Market: Polyurea Coatings Market Size Was Valued at USD 0.8 Billion in 2023, and is Projected to Reach USD 1.4 Billion by 2032, Growing at a CAGR of 6.6% From 2024-2032.

Industrial Bakeware Market: Industrial Bakeware Market Size is Valued at USD 2.82 Billion in 2023 and is Projected to Reach USD 4.27 Billion by 2032, Growing at a CAGR of 9.10% From 2024-2032.

Cool Roof Market: Cool Roof Market Size Was Valued at USD 24389.51 Million in 2023 and is Projected to Reach USD 39827.07 Million by 2032, Growing at a CAGR of 5.6% From 2024-2032.

Architectural Coatings Market: Architectural Coatings Market Size Was Valued at USD 74.75 Billion in 2023 and is Projected to Reach USD 88.27 Billion by 2032, Growing at a CAGR of 5.7% From 2024-2032.

Phenolic Resin Market: Phenolic Resin Market Size is Valued at USD 15.08 Billion in 2024, and is Projected to Reach USD 23.15 Billion by 2032, Growing at a CAGR of 5.50% From 2024-2032.

Paints and Coatings Market: Paints and Coatings Market size is estimated at USD 147.33 billion in 2023 and is expected to reach USD 214.28 billion by 2032, growing at a CAGR of 4.25% during the forecast period (2024-2032).

Premium Paper Market: Premium Paper Market Size Was Valued at USD 112.11 Billion in 2023, and is Projected to Reach USD 299.34 Billion by 2032, Growing at a CAGR of 11.53 % From 2024-2032.

North America Floor Coatings Market: The North America Floor Coatings Market size was valued at USD 699.28 Million in 2023 and is projected to reach USD 1286.68 Million by 2032, growing at a CAGR of 7.01 % from 2024 to 2032.

About Us:

Introspective Market Research is a leading global market research firm that utilizes big data and advanced analytics to deliver strategic insights and consulting solutions, enabling clients to anticipate future market trends. Our expert team at IMR helps businesses gain a thorough understanding of both historical and current market dynamics, providing a clear perspective on future developments.

With a strong professional network among industry-leading companies, we have access to crucial market data, which allows us to create accurate research data tables and ensure precise market forecasts. Under the guidance of CEO Mrs. Swati Kalagate, who promotes a culture of excellence, we are dedicated to providing high-quality data that assists our clients in reaching their business objectives.

The insights presented in our reports are based on primary interviews with key executives from top companies in relevant industries. Additionally, our comprehensive secondary data collection process involves extensive online and offline research, along with detailed discussions with knowledgeable industry professionals and analysts.

Contact Us:

Canada Office

Introspective Market Research Private Limited, 138 Downes Street Unit 6203- M5E 0E4, Toronto, Canada.

APAC Office

Introspective Market Research Private Limited, Office No. 401, Saudamini Commercial Complex, Kothrud, Pune, India 411038

Ph no: +91-81800-96367 / +91-7410103736

Email: sales@introspectivemarketresearch.com

LinkedIn| Twitter| Facebook | Instagram

Ours Websites : https://introspectivemarketresearch.com | https://imrknowledgecluster.com/knowledge-cluster | https://imrtechsolutions.com | https://imrnewswire.com/ | https://marketnresearch.de |