NEWARK, Del, March 20, 2025 (GLOBE NEWSWIRE) -- The global industrial air compressor market is poised for significant expansion, with the market size projected to grow from USD 3.6 billion in 2025 to USD 7.7 billion by 2035, registering a CAGR of 7.9%. This growth is fueled by the rising demand for power-saving compressed air systems, the expansion of manufacturing activities, and ongoing infrastructure advancements worldwide.

Industrial air compressors play a crucial role across industries, facilitating operations from driving machinery and tools to maintaining consistent air pressure for advanced processes. Their importance is evident in various applications, including automotive, healthcare, food processing, and high-value manufacturing sectors.

North America continues to be the technological hub for industrial air compressors, particularly in energy-efficient and environmentally friendly solutions. The U.S. and Canada, with their technologically advanced industries, drive the growing demand for high-efficiency compression systems.

Additionally, the presence of large-scale manufacturers and government incentives for energy-efficient equipment has fueled investments in Variable Speed Drive (VSD) and oil-free air compressors. These developments reflect the broader trend of industries shifting towards sustainable and cost-effective air compression solutions.

Gain Valuable Insights from Industry Experts to Shape Your Growth Strategies. Access our Sample Report Now https://www.futuremarketinsights.com/report-sample#5245502d47422d32383835

Which Drivers Underpin Industrial Air Compressor Industry Expansion?

Increase in Demand for Energy-Efficient Air Compressors to Drive the Growth of the Market During the Forecasting Period

The demand for industrial air compressors market is projected to surge during the forecast period due to their usage in various industrial applications. Industrialization is gaining momentum in developing nations such as China, India, Russia, and others.

The demand for air compressors is majorly rising from the oil & gas sector due to their extensive application in oil & gas transportation pipelines. Substantial increase in investments for brownfield and greenfield projects, coupled with planned cross-country pipeline projects, is expected to create positive prospects for growth in demand over the coming years.

Competitive price offering and rise in end-user satisfaction by providing innovative and customized products according to the end user requirements are the result of enhanced R&D activities. Moreover, establishing sales and service facilities in emerging countries, coupled with long-term partnerships with regional distributors, is also paving the way for the expansion of the reach of market players.

Technological Advancements in Air Compressors to Boost the Sales

Adoption of advanced technologies by global players in the air compressor market is fueling the demand for air compressors in different industries. Technological innovation is a prominent factor in the air compressor market, which results in significant replacement demand for traditional air compressors.

Manufacturers in the industrial air compressor market are setting their collaboration wheels in motion to innovate in reciprocating compressors. Compressed air & gas system specialist. For instance, the Titus Company is partnering with multiple equipment manufacturers such as Sauer Compressors to increase their portfolio in reciprocating high-pressure air compressors.

Manufacturers are vying opportunities to work with equipment manufacturers that have an extensive experience in oil & gas, military and shipping industries. As such, there is a high demand for affordable industrial air compressors that are delivered on time.

Key Factors Shaping Market Dynamics

High Energy Consumption and Maintenance Costs

Despite their benefits, industrial air compressors are energy-intensive, with electricity costs accounting for a significant portion of operational expenses. Businesses are increasingly investing in energy-efficient systems to mitigate high power consumption and reduce maintenance costs.

Manufacturers are introducing oil-free and variable-speed compressors to address these concerns. These innovations help in reducing carbon emissions, improving air quality, and enhancing overall efficiency.

Growth in Smart Manufacturing and Energy-Efficient Solutions

Industries are rapidly transitioning towards smart manufacturing, integrating IoT-enabled and AI-driven air compressors for real-time monitoring and predictive maintenance. Such advancements enhance performance while reducing downtime and operational costs.

Moreover, the adoption of energy-efficient air compressors aligns with sustainability goals as companies seek to minimize their carbon footprint. Government policies supporting low-energy industrial equipment further accelerate this shift.

Browse Full Report Here: https://www.futuremarketinsights.com/reports/industrial-air-compressor-market

Industrial Automation Boosting Air Compressor Adoption

The rise of industrial automation is a crucial factor in driving air compressor demand. Automated production lines, robotic assembly units, and CNC machines rely on compressed air for consistent operation.

With automation becoming a standard across industries, the demand for high-performance and reliable air compressors is expected to surge. Advanced control systems that optimize air delivery and reduce energy waste are gaining traction among manufacturers.

Key Analyst Comment

"The industrial air compressor market is undergoing a transformation driven by energy efficiency, automation, and sustainability goals. As industries focus on reducing their operational carbon footprint, the shift towards oil-free and variable-speed compressors will define the future of this sector. The expansion of manufacturing activities worldwide, coupled with government incentives for energy-efficient equipment, will ensure steady growth over the next decade," opines Nikhil Kaitwade, Associate Vice President at Future Market Insights (FMI)

Key Takeaways

- The global industrial air compressor market is projected to grow at a CAGR of 7.9% from 2025 to 2035.

- Smart manufacturing and automation trends are driving demand for advanced air compressors.

- North America remains a key technology hub, with strong investments in energy-efficient solutions.

- Oil-free and variable-speed air compressors are gaining traction due to environmental concerns.

- Expanding industrial infrastructure projects worldwide contribute to long-term market growth.

Increasing Focus on Sustainable and Oil-Free Air Compression

Governments and regulatory bodies are emphasizing sustainable industrial practices, encouraging the adoption of oil-free air compressors to minimize environmental impact.

Leading manufacturers are investing in next-generation technologies that enhance energy efficiency while maintaining high performance. Innovations in compressor design, material usage, and AI integration are set to redefine industrial air compression.

Which Factors Are Limiting the Growth of the Industrial Air Compressor Market?

The high cost of maintenance of air compressors may restrain the growth of the market.

The high cost of installation and maintenance of air compressors. The cost continues to rise, owing to the maintenance of complicated monitoring and control systems of different types of air compressors. This is expected to hinder the market growth in the near future.

Difficulty in maintenance affecting the industrial air compressor market growth

Although industrial air compressors are largely used in various end-user industries, their complex nature of handling the same is restraining the growth of the same.

Industrial Air Compressor Market Category-Wise Insights

By technology, which Industrial Air Compressor will remain prominent?

Rotary Type Segment of Industrial Air Compressor the to Beat Competition in Untiring Market

The rotary type industrial air compressors accounts for nearly 30% sales in the market. This is due to the growing demand for air and gas compression across industries drives the need for positive displacement air compressor. Demand for rotary compressors will remain high due to their increasing application in various end-use sectors.

Technological advancements by manufacturers to provide satisfactory solutions to end users are enhancing the application of rotary compressors. They also have a long lifespan and low maintenance costs comparatively, which makes them more preferable for end users.

By Driver Type, which Industrial Air Compressor Category to dominate?

Electric Segment to Drive the Industrial Air Compressor Market

Industrial air compressors are used for applications across diverse industries. This has been fuelling the demand for electric-driven air compressors. They are the cheapest drivers available in the market, which is a key factor driving sales within the category.

Moreover, electric drivers offer simplicity of operations and have less maintenance costs, which is also a key advantage. Electric drivers offer various operating capacity ranges, which enhances their applications in various applications.

By Capacity Which Type Will Generate More Sales in Industrial Air Compressor Market?

Based On Capacity 0HP-50HP Segment to Boost the Sales of Industrial Air Compressor

The capacity segment of 0 HP to 500 HP will exhibit increasing sales due to rising application of this type of air compressors in various end-use sectors. This capacity range holds more than half of the market share in industrial air compressors. Air compressors of this capacity are cost-effective and consume less space, which make them suitable for various end uses.

By End User, which Industrial Air Compressor Category to dominate?

The oil & Gas Industry Provides Opportunities for Growth of the Market.

Industrial air compressor manufacturers will experience rising demand from various industries. Oil & gas sector will exhibit considerably high demand for industrial air compressors.

Investment aimed at expansion of the oil industry will therefore support the growth of the market.

Which is the Preferred Compression Stage?

By compression stage, double compression stage industrial air compressors will have higher demand than the rest due to their cost efficiency. According to the study, it is expected to account for over 46% of the market in 2024 in terms of compression stage.

Industrial Air Compressor Market Key Players

The market is dominated by key players focusing on innovation, efficiency, and sustainability:

- Atlas Copco AB – Leading provider of advanced oil-free air compressors and smart air solutions.

- Ingersoll Rand Inc. – Offers high-efficiency industrial and portable air compression systems.

- Gardner Denver Holdings – Specializes in customized compressed air and vacuum solutions.

- Kaeser Kompressoren SE – Pioneering low-maintenance, high-performance air compressor technology.

- Hitachi Industrial Equipment Systems Co., Ltd. – Focuses on energy-efficient and intelligent air compression systems.

Demand Surge from Manufacturing and Process Industries

With increased production across automotive, pharmaceuticals, food & beverage, and electronics industries, the demand for high-performance air compressors is escalating. Manufacturers seek cost-effective, durable, and eco-friendly solutions to maintain productivity.

Moreover, the push for precision engineering and advanced manufacturing techniques necessitates the adoption of high-quality air compression systems to ensure seamless operations.

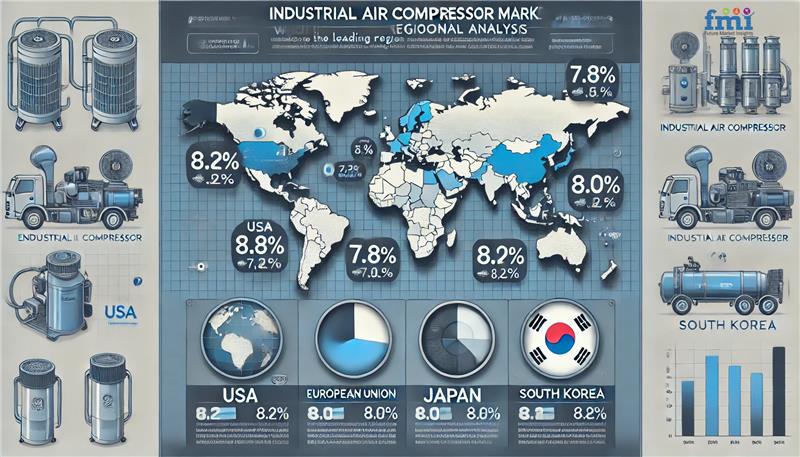

Regional Analysis

- North America: Leading market with a focus on energy-efficient and eco-friendly air compression technologies.

- Latin America: Increasing industrial investments drive demand for high-performance compressors.

- Western & Eastern Europe: Strong presence of automotive and manufacturing industries boosts market growth.

- Asia-Pacific: Rapid industrialization, especially in China, India, and Southeast Asia, fuels air compressor demand.

- Middle East & Africa: Expansion of oil & gas, mining, and infrastructure projects creates new market opportunities.

Latest Operational Equipment Reports: https://www.futuremarketinsights.com/industry-analysis/operational-equipment

Industrial Air Compressor Market Segmentation

By Technology:

- Rotary Industrial Air Compressor

- Reciprocating Industrial Air Compressor

- Centrifugal Industrial Air Compressor

- Axial Industrial Air Compressor

By Capacity:

- Up to 500 HP

- 500 to 2000 HP

- 2000 to 5000 HP

- 5000 to 12000 HP

- 12000 to 20000 HP

- Above 20000 HP

By Compression Stage:

- Single Stage Industrial Air Compressor

- Double Stage Industrial Air Compressor

- Multistage Industrial Air Compressor

By Driver Type:

- Electric Industrial Air Compressor

- Natural Gas Industrial Air Compressor

- Fuel Driven Industrial Air Compressor

By End Use:

- Automotive and Transportation

- Oil and Gas

- Power Generation

- Chemicals

- Food and Beverages

- Pharmaceuticals

- Mining and Metals

- Industrial Air Separation

- Other Manufacturing

By Region:

- North America

- Latin America

- Western Europe

- Eastern Europe

- East Asia

- South Asia Pacific

- Middle East and Africa

Explore FMI’s Extensive Coverage on Industrial Automation Domain:

The Truck Mounted Cranes Market sale is projected to grow from USD 2,751.1 million in 2025 to USD 4,243.6 million by 2035, registering a CAGR of 4.4%

global sales of trigger sprayer market is anticipated to reach a value of USD 870.7 million by 2035. Sales are projected to rise at a CAGR of 4.2%.

The bitumen sprayer market size is anticipated to reach a value of USD 1,404 million by 2034. Sales are projected to rise at a CAGR of 4%

By 2033, the global market for size air quality monitoring equipment is expected to grow at a CAGR of 7.3% to reach a worth of USD 13.3 billion.

In 2025, the size of the global asphalt pavers market is anticipated to reach USD 2,526.5 million. Global sales are expected to grow at a 4.4% CAGR, reaching a market value of USD 3,886.3 million by 2035.

In 2025, the size of the global asphalt pavers market is anticipated to reach USD 2,526.5 million. Global sales are expected to grow at a 4.4% CAGR, reaching a market value of USD 3,886.3 million by 2035.

The global compact construction equipment market is projected to grow at a CAGR of 3.8% from 2023 to 2033, reaching USD 325.4 billion by that year.

The sorting equipment market sale is expected to reach USD 8.9 billion by 2033, growing at a CAGR of 7.9% from 2023 to 2033.

The conveyor system market forecast will grow at a 5.5% CAGR between 2024 and 2034, reaching around USD 11,375 million by 2034.

By 2034, the glass reactor market size is expected to grow at a compound annual growth rate of 5.9% and reach a valuation of USD 1,826.5 million.

About Future Market Insights (FMI):

Future Market Insights (FMI) is a leading provider of market intelligence and consulting services, serving clients in over 150 countries. FMI is headquartered in Dubai, and has delivery centers in the UK, U.S. and India. FMI's latest market research reports and market analysis help businesses navigate challenges and make critical decisions with confidence and clarity amidst breakneck competition. Our customized and syndicated market research reports deliver actionable insights that drive sustainable growth. A team of expert led analysts at FMI continuously tracks emerging trends and events in a broad range of industries to ensure that our clients prepare for the evolving needs of their consumers.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn | Twitter | Blogs | YouTube