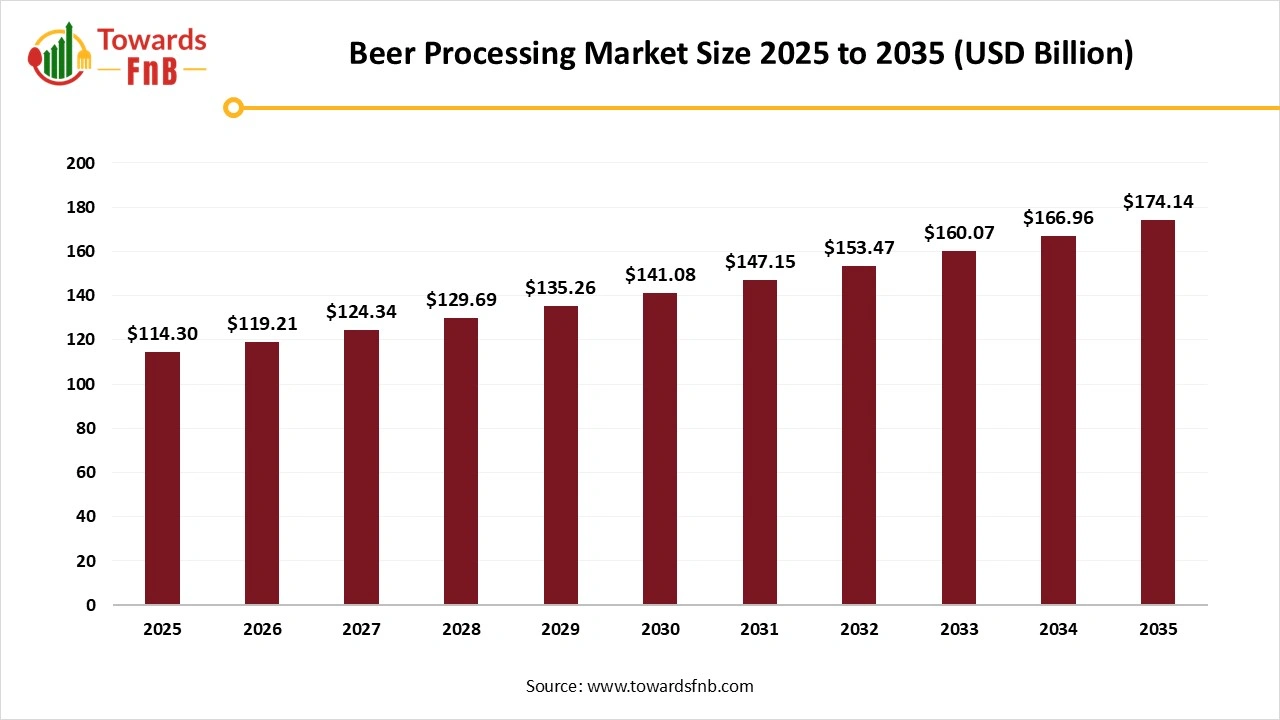

Ottawa, Dec. 15, 2025 (GLOBE NEWSWIRE) -- The global beer processing market size stood at USD 114.30 billion in 2025 and is anticipated to grow from USD 119.21 billion in 2026 to reach around USD 174.14 billion by 2035, according to a report published by Towards FnB, a sister firm of Precedence Research.

A key driver of market growth is the surge in demand for health-conscious beer options, including low-alcohol, non-alcoholic, and organic variants. Additionally, the expanding middle-class population worldwide and the rising preference for unique flavor profiles such as fruity, citrusy, and hoppy beers are contributing to the market’s upward trend. Craft and specialty beers, often leveraging artisanal brewing methods, continue to attract consumers seeking premium experiences.

Note: This report is readily available for immediate delivery. We can review it with you in a meeting to ensure data reliability and quality for decision-making.

Access the Full Study Instantly | Download Sample Pages of the Report Now@ https://www.towardsfnb.com/download-sample/5948

Key Highlights of the Beer Processing Market

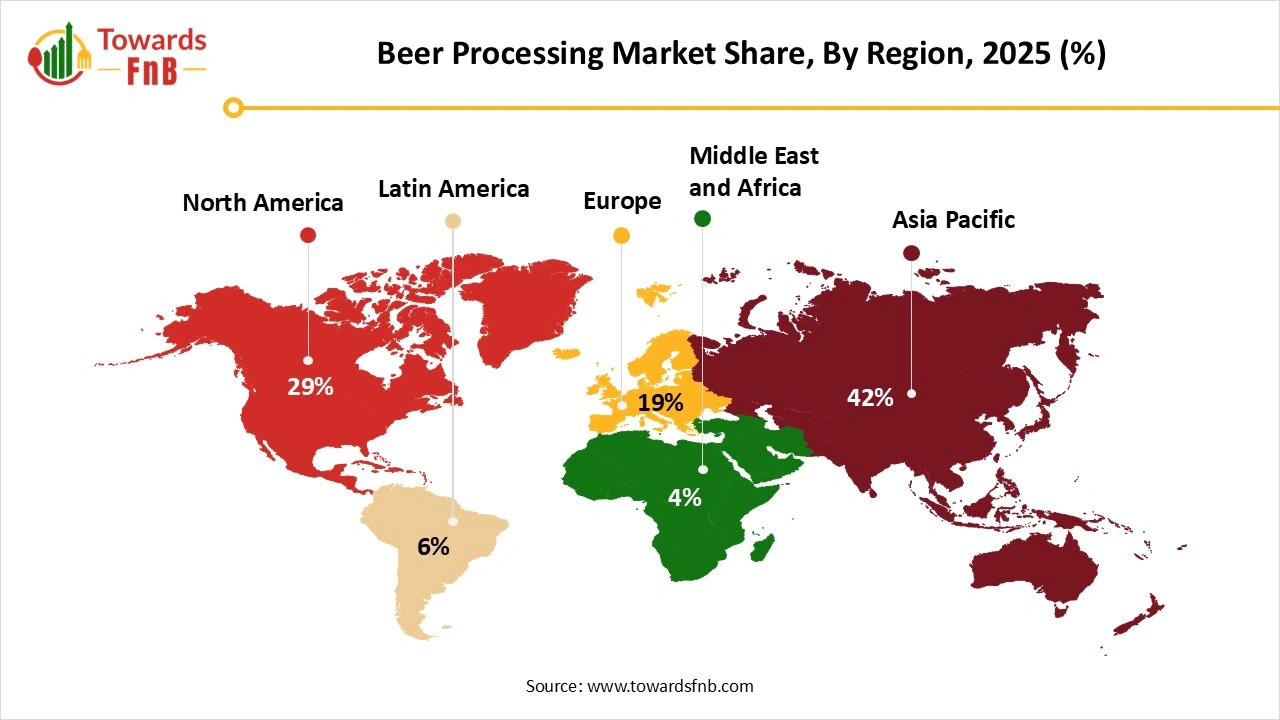

- By region, Asia Pacific dominated the global beer processing market with the largest share in 2025, while North America is expected to register the fastest growth during the forecast period (2026–2035).

- By raw material type, the malt segment held the major market share in 2025, whereas the hops segment is projected to grow at a notable CAGR from 2026 to 2035.

- By processing method, the brewing segment contributed the largest market share in 2025, while the filtration segment is expected to expand at a significant CAGR over the forecast period.

- By type, the lager segment dominated the market in 2025, whereas the ale segment is anticipated to grow at a significant CAGR during the projected period.

- By packaging format, the kegs segment held the major market share in 2025, while the cans segment is expected to grow at a strong CAGR between 2026 and 2035.

Availability of Stable, Safe, and Consumer-Friendly Options helps to fuel the Growth of the Beer Processing Industry

The beer processing market is expected to grow due to high demand for premium and specialty beer options, higher demand for low-alcohol or no-alcohol options, and technological innovations in the industry. The market relates to the industrial activities involved in transforming the raw materials, such as malted barley, hops, yeast, and water, into a finished and organic beer.

The procedure involves multiple stages such as fermentation, maturation, brewing, and packaging. All the stages help in the development of specialty and craft beer options, which are beneficial for market growth. The main aim of the market is to provide a specialized, craft, premium, stable, safe, and diverse range of products to meet the needs of social occasions, further fueling market growth.

Technological Advancements are helpful for the Growth of the Market

Technological innovations in the form of AI and IoT are one of the major factors helpful for the growth of the beer processing market. Technological procedures and aids at every step of the market, such as brewing, filtration, and packaging, help ease the process and reduce manual intervention. It also helps lower the risk of human error, further fueling the market's growth. Using fully automated systems, sensors, and programmable logic controllers to collect real-time data, such as temperature, pressure, and pH levels, further fuels the market's growth.

Impact of AI in the Beer Processing Market

Artificial intelligence (AI) is influencing the beer processing market by improving process control, product consistency, and operational efficiency across brewing operations. In recipe development, AI models analyze malt composition, hop profiles, yeast behavior, and historical batch data to predict flavor outcomes, bitterness levels, and aroma stability. Brewers use these insights to fine-tune grain bills and hopping schedules while maintaining consistent sensory profiles across large production volumes and seasonal variants.

During brewing, AI-driven control systems monitor mash temperature curves, pH, enzyme activity, and wort gravity in real time. Machine learning models adjust heating rates, rest times, and lautering conditions to improve extract yield and reduce variability. Fermentation management has become more precise as AI analyzes yeast vitality, sugar conversion rates, and dissolved oxygen levels. These systems predict the completion of fermentation and identify deviations that could lead to off-flavors or stalled fermentation.

View Full Market Intelligence@ https://www.towardsfnb.com/insights/beer-processing-market

Recent Developments in Beer Processing Market

- In March 2021, Camikara announced its partnership with Fort City Brewing to unveil ‘Mridya’- India’s first ex-rum barrel-aged beer. The partnership of India’s first and only pure cane juice aged rum with Delhi’s most innovative craft beer makers aims to elevate craft beer by infusing it with rich and aged characteristics of Camikara rum.

- In September 2025, Fathers Beer officially announced the launch of its cleanest beer tasting in America. The procedure of making beer involves double-filtration for removing heavy metals, forever chemicals, and microplastics.

Beer Processing Market Dynamics

What are the Growth Drivers of Beer Processing Market?

Major factors such as demand for premiumization, intense, strong, citrusy, and fruity flavor options are some of the major factors for the growth of the market. Higher demand for innovative and premium craft beer options is another major factor driving market growth. Growing consumer preferences, rising disposable incomes, and shifting consumer behavior also aid the market’s growth. Innovative technologies that help enhance the shelf life of beer, along with the use of eco-friendly filtration processes, are another major factor driving the market's growth. Higher demand for low-alcoholic, non-alcoholic, and organic options among health-conscious consumers is another major factor driving market growth.

Challenge

Regulatory and Economic Hurdles hampering the Market’s Growth

Different state regulations, taxes, and distribution rules are among the issues hampering the market's growth. Other major issues, such as excise duties, state-specific laws, and beer prices, also hamper the market's growth. Hence, such factors may collectively create issues for the market's growth.

Opportunity

Increased Health Awareness is helpful for the market’s Growth

Higher demand for low-alcoholic, non-alcoholic, and organic options, driven by product development and technological innovations, is a major opportunity for market growth. Such options have a unique flavor profile, along with conscious brewing and filtration, further fueling the market's growth. Hence, such factors help the market grow in the foreseeable period.

Top Products in the Beer Processing Market

| Product Category | Description or Function | Common Equipment Types or Variants | Key Applications or Brewery Segments | Representative Manufacturers or Suppliers |

| Brewhouse Systems | Integrated systems for wort production including mashing, lautering, boiling, and whirlpooling. | Two vessel brewhouse, three vessel brewhouse, automated brewhouse systems | Craft breweries, industrial breweries | Krones Steinecker, GEA Brewery Systems |

| Mash Tuns and Lauter Tuns | Vessels used to convert starches to fermentable sugars and separate wort from spent grains. | Combination mash lauter tun, separate mash and lauter vessels | All brewery scales | Kaspar Schulz, SS Brewtech |

| Wort Boiling and Whirlpool Systems | Systems designed for wort sterilization, hop addition, and trub separation. | Internal calandria kettles, external wort boilers | Lager and ale production | Ziemann Holvrieka, Krones |

| Fermentation Tanks | Temperature controlled vessels used for yeast driven fermentation. | Cylindroconical tanks, unitanks, open fermenters | Craft and industrial breweries | GEA, JVNW, DME Brewing Solutions |

| Yeast Propagation Systems | Equipment used to grow and manage yeast cultures. | Yeast brink systems, propagation tanks | Breweries with in house yeast management | Alfa Laval, GEA |

| Beer Filtration Systems | Systems that clarify beer by removing yeast and particulates. | Kieselguhr filters, crossflow membrane filtration | Clear beer styles, lager production | Pall Corporation, Alfa Laval |

| Centrifuges and Separators | Mechanical separation equipment used to clarify beer. | Disc stack centrifuges | Large scale breweries, craft brewers upgrading filtration | Alfa Laval, GEA |

| Beer Stabilization Systems | Equipment used to improve shelf life and prevent haze formation. | PVPP stabilizers, silica gel systems | Packaged beer for distribution | Pentair, KHS |

| Carbonation Systems | Equipment that dissolves carbon dioxide into beer. | Inline carbonators, CO2 dosing systems | Packaged beer production | Pentair, Krones |

| Pasteurization Systems | Thermal treatment systems for microbial stabilization. | Tunnel pasteurizers, flash pasteurizers | Bottled and canned beer | KHS, Tetra Pak |

| Cold Block and Cooling Systems | Systems for chilling beer during processing and fermentation. | Glycol chillers, plate heat exchangers | All brewery sizes | GEA, Alfa Laval |

| Beer Storage and Bright Beer Tanks | Tanks used for maturation, carbonation, and final storage. | Bright beer tanks, lagering tanks | Packaging preparation | Ziemann Holvrieka, DME |

| Bottling Lines | Equipment for filling and sealing beer bottles. | Glass bottle fillers, crown cappers | Bottled beer production | Krones, Sidel |

| Canning Lines | High speed systems for filling and sealing cans. | Can fillers, seamers, depalletizers | Craft and industrial canning | Krones, Wild Goose Filling |

| Kegging Systems | Equipment for cleaning, filling, and sealing kegs. | Semi automatic keg washers, high speed keg lines | Draft beer markets | KHS, Comac |

| Cleaning in Place Systems | Automated cleaning systems for hygienic brewery operations. | CIP skids, automated cleaning loops | All brewery operations | GEA, Alfa Laval |

| Utilities and Energy Recovery Systems | Systems designed to improve energy and water efficiency. | Heat recovery systems, water reuse modules | Sustainable brewery operations | Krones, Veolia |

| Process Automation and Brewery Control Software | Digital systems controlling and monitoring beer production processes. | PLC based automation, SCADA systems | Large and smart breweries | Siemens, Rockwell Automation |

| Quality Control and Inspection Equipment | Analytical tools for ensuring beer quality and consistency. | CO2 meters, turbidity meters, alcohol analyzers | Brewery laboratories | Anton Paar, Mettler Toledo |

Beer Processing Market Regional Analysis

Asia Pacific led the Beer Processing Market in 2025

Asia Pacific dominated the beer processing market in 2025, mainly due to factors such as growing disposable income, a growing middle-class population, and higher demand for specialty, premium, craft, and lager options at the mass level. High population and consumption volumes are other major factors driving market growth. Countries such as India and China have a major contribution to the growth of the market due to a huge population base, booming craft breweries providing intense, bold, and unique flavor profiles, technological innovations in brewing, and availability of organic and non-alcoholic options.

North America is Observed to Be the Fastest-Growing Region in the Foreseeable Period

North America is expected to be the fastest-growing region in the forecast period due to high disposable income, higher demand for premium and craft beer options, and higher demand for unique, bold, and citrusy flavor profiles, which are among the major factors driving market growth. The region also observed growth due to the availability of technologically advanced methods helpful for crafting and filtration of unique and premium beer options.

The availability of organic, low-alcoholic, and non-alcoholic options is another major factor supporting the growth of the beer processing market in the foreseeable period. The US has a major contribution to the market's growth due to higher demand for NOLO, premium, and craft beer options, further fueling growth.

Europe is observed to have a Notable Growth in the Foreseen Period

Europe is expected to grow over the forecast period due to higher demand for craft and premium beer in the region, the availability of technologically advanced brewing methods, such as AI and IoT, and higher consumer expenditure on premium and organic options. Higher demand for low-alcohol and no-alcohol options by health-conscious consumers is another major factor for the growth of the market. Germany has made a major contribution to the region's market growth due to higher demand for specialty and premium beer options among consumers.

For Detailed Pricing and Tailored Market Report Options, Click Here: https://www.towardsfnb.com/checkout/5948

Trade Analysis for the Beer Processing Market

What is actually traded (product forms)

- Brewing machinery and equipment, such as kettles, fermenters, and filtration systems, are typically classified under HS 8438 (machinery for industrial preparation of food or drink).

- Malted barley and cereal adjuncts used in brewing are commonly classified under HS 1107 for malt and HS 1003 for barley.

- Hops and hop products, including pellets and extracts, are classified under HS 1210 and HS 1302 for extracts.

- Brewing yeasts, enzymes, and processing aids are often declared under HS 2102 for yeast and HS 3507 for enzymes.

- Packaging-related processing systems, such as filling and pasteurisation equipment, are usually recorded under HS 8422 and related machinery headings.

Top Exporters (supply hubs)

- Germany: major exporter of brewing equipment and processing technology, supported by long-established engineering firms and a strong domestic brewing sector.

- Italy: a significant exporter of mid-scale and craft-brewery processing systems, particularly brewhouses and fermentation vessels.

- United States: exporter of specialised craft-brewing equipment, hop products, and proprietary yeast strains.

- Czech Republic: exporter of brewing technology and hop products, linked to its brewing heritage and hop-growing regions.

Top Importers (demand centres)

- China: a large importer of brewing equipment and processing systems to support industrial breweries and expanding craft segments.

- United States: imports specialised processing equipment and hop varieties not domestically available in sufficient quantity.

- Brazil and Mexico: fast-growing beer markets that import brewing machinery and processing inputs to expand capacity.

- Southeast Asia: countries such as Vietnam and Thailand import brewing systems and ingredients to support new breweries and contract brewing operations.

Typical Trade Flows and Logistics Patterns

- Brewing equipment flows primarily from Europe and North America to the Asia Pacific, Latin America, and emerging African markets via containerised sea freight.

- Malted barley and hops move from major agricultural producers in Europe, North America, and Australia to breweries worldwide, often under long-term supply contracts.

- Yeast cultures and enzymes are shipped in temperature-controlled conditions, frequently by air for high-value proprietary strains.

- Installation and commissioning of processing equipment often involve bundled trade in machinery, spare parts, and on-site technical services.

Trade Drivers and Structural Factors

- Brewery capacity investment cycles are linked to consumer demand, premiumisation, and craft-beer growth.

- Efficiency and sustainability pressures are driving upgrades in water use, energy recovery, and waste reduction systems.

- Consolidation among large brewers is influencing procurement scale and supplier concentration.

- Growth of non-alcoholic and low-alcohol beer categories requires specialised processing technologies.

- Agricultural variability affects the availability and pricing of malted barley and hops.

Regulatory, Quality and Market-Access Considerations

- Brewing equipment must comply with food-contact material regulations, pressure-vessel standards, and electrical safety rules in importing markets.

- Malt, hops, and yeast are subject to food-safety, phytosanitary, and contaminant limits, including pesticide-residue thresholds.

- Alcohol production regulations and licensing requirements can delay commissioning and affect import timelines for equipment.

- Documentation typically includes certificates of origin, conformity declarations, and, for biological inputs, certificates of analysis.

Government Initiatives and Public-Policy Influences

- Agricultural support programs for barley and hop growers influence the upstream ingredient supply available for export.

- Energy and water efficiency regulations in the EU and other regions encourage investment in advanced brewing technologies.

- Trade promotion and export-credit programs in Germany, Italy, and the United States support international sales of brewing machinery.

- Excise-tax structures and alcohol policy reforms indirectly affect brewery investment decisions and equipment demand.

Beer Processing Market Report Scope

| Report Attribute | Key Statistics |

| Base Year | 2025 |

| Forecast Period | 2026 to 2035 |

| Growth Rate from 2026 to 2035 | CAGR of 4.3% |

| Market Size in 2026 | USD 119.21 Billion |

| Market Size in 2027 | USD 124.34 Billion |

| Market Size by 2035 | USD 174.14 Billion |

| Dominated Region | Asia Pacific |

| Fastest Growing Region | North America |

| Regions Covered | North America, Europe, Asia-Pacific, Latin America and Middle East & Africa |

Have Questions? Let’s Talk—Schedule a Meeting with Our Insights Team: https://www.towardsfnb.com/schedule-meeting

Beer Processing Market Segmental Analysis

Raw Material Analysis

The malt segment led the beer processing market in 2025, as malt's main function is to provide carbohydrates and sugars for yeast fermentation, which produces alcohol and carbon dioxide. Without malt, the main beer processing procedure will be incomplete. Hence, the segment has a major role in the growth of the market. The segment also observes growth as malt is the epicenter of providing flavor, aroma, color, high volume, and visible nutritional properties to the drink, further fueling the growth of the market.

The hops segment is expected to be the fastest-growing over the forecast period due to higher demand for premium, craft, and hop-forward-style IPAs. Consumers today prefer intense beer flavors compared to light bitterness. Hence, such factors help fuel the market's growth. Higher demand for intense, fruity, citrusy, and aromatic flavors provided by hop-style beers is another major factor driving market growth in the foreseeable period.

Processing Method Analysis

The brewing segment led the beer processing market in 2025, as it is a crucial step in the industry. The segment involves a huge investment in setting up heavy machinery and equipment required for the brewing procedure. Machines such as mash kettles, lauter tuns, wort kettles, and steam generators are essential to the brewing process and also support market growth. Brewing helps to improve the consistency and quality of beer, which helps to enhance the product, along with the aid of innovative brewing techniques. Hence, the segment has a major role in the growth of the market.

The filtration segment is observed to be the fastest-growing in the foreseen period due to the enhancement of technological innovations, and the adoption of sustainable methods is one of the major factors for the growth of the market. Adoption of eco-friendly membranes and cross-flow filtration systems helps to fuel the growth of the market in the foreseen period, along with maintaining sustainability. Higher demand for aesthetically clear beers with extended shelf life is another major factor for the growth of the market.

Type Analysis

The lager segment dominated the beer processing market in 2025, due to the availability of new flavor profiles with unique taste by multiple brands and craft breweries. Availability of premium lagers, low-calorie options, and health-conscious and non-alcoholic versions is another major factor for the growth of the market. The market also observes growth due to historical significance, affordability, and mass production efficiency.

The ale segment is observed to be the fastest-growing in the foreseen period due to higher demand for intense, fruity, citrusy, and bold flavors, further fueling the growth of the market. Ale yeasts are perfect for small batches and high production turnover cycles, further fueling market growth in the foreseen period. Availability of innovative, flavorful, and unique flavor ale with intense flavors, also available in non-alcoholic and hazy IPAs, further fuels the growth of the market in the foreseen period. Hence, consumers with healthier preferences also help to fuel the market’s growth.

Packaging Format Analysis

The kegs segment led the beer processing market in 2025, due to higher demand for artisanal, premium, and aesthetically pleasing craft beers, fueling the growth of the market. Higher demand for reusable and recyclable kegs is another major factor for the growth of the market. Technological innovations in the form of smart tracking and automated cleaning systems are another major factor for the growth of the market.

The cans segment is observed to be the fastest-growing segment in the foreseen period, as they are lightweight, innovative, easily portable, and easy to stack, further fueling the growth of the market. They also help to protect beer from light and oxygen to maintain the shelf life of the product, which is essential for the growth of the market. The segment also observes growth due to the availability of craft beers, convenient packaging, aesthetic looks, and sustainable materials, further fueling the growth of the market.

Feel Free to Get in Touch with Us for Orders or Any Questions at: sales@towardsfnb.com

Additional Topics Worth Exploring:

- Dietary Supplements Market: The dietary supplements market size is projected to reach USD 464.58 billion by 2034, growing from USD 192.68 billion in 2025, at a CAGR of 9.2% from 2025 to 2034.

- Frozen Food Market: The global frozen food market size is expected to grow from USD 214.32 billion in 2025 to reach around USD 347.01 billion by 2034, at a CAGR of 5.5% over the forecast period from 2025 to 2034.

- Vegan Food Market: The global vegan food market size is evaluated at USD 22.38 billion in 2025 and is expected to reach USD 55.88 billion by 2034, with a CAGR of 10.7% during the forecast period from 2025 to 2034.

- Sugar-Free Food Market: The global sugar-free food market size is expected to grow from USD 48.14 billion in 2025 to USD 83.2 billion by 2034, growing at a CAGR of 6.27% during the forecast period from 2025 to 2034.

- Food Additives Market: The global food additives market size is rising from USD 128.14 billion in 2025 to USD 214.66 billion by 2034. This projected expansion reflects a CAGR of 5.9% throughout the forecast period from 2025 to 2034.

- Ethnic Food Market: The global ethnic food market size is forecasted to expand from USD 93.47 billion in 2025 to reach around USD 179.21 billion by 2034, growing at a CAGR of 7.5% during the forecast period from 2025 to 2034.

- Meal Kits Market: The global meal kits market size is projected to rise from USD 17.11 billion in 2025 to approximately USD 58.8 billion by 2034, registering a CAGR of 14.7% during the forecast period from 2025 to 2034.

- Baking Ingredients Market: The global baking ingredients market size is projected to grow from USD 18 billion in 2025 to around USD 31.72 billion by 2034, at a CAGR of 6.5% during the forecast period from 2025 to 2034.

- Fresh Produce Market: The global fresh produce market size is projected to grow from USD 3,707 billion in 2025 to approximately USD 5,653 billion by 2034. This anticipated growth represents a CAGR of 4.80% during the forecast period from 2025 to 2034.

- Beverage Packaging Market: The global beverage packaging market size is projected to reach USD 271.80 billion by 2034, growing from USD 173.71 billion in 2025, at a CAGR of 5.1% during the forecast period from 2025 to 2034.

- Coconut Products Market: The global coconut products market size is expected to climb from USD 14.18 billion in 2025 to approximately USD 33.71 billion by 2034, growing at a CAGR of 10.1% during the forecast from 2025 to 2034.

- Pet Food Market: The global pet food market size is expected to increase from USD 113.02 billion in 2025 to USD 167.97 billion by 2034, growing at a CAGR of 4.5% throughout the estimated timeframe from 2025 to 2034.

- Organic Food Market: The global organic food market size is expected to grow from USD 253.96 billion in 2025 to USD 660.25 billion by 2034, with a compound annual growth rate (CAGR) of 11.20% during the forecast period from 2025 to 2034.

Top Companies in the Beer Processing Market

- Heineken N.V.: A Dutch multinational brewing company, Heineken is one of the world’s largest beer producers, with a portfolio of over 300 international, regional, and local brands, known for its flagship Heineken lager and global distribution network.

- Carlsberg A/S: Headquartered in Denmark, Carlsberg is a leading global brewer with strong market presence in Europe and Asia, offering popular brands such as Carlsberg, Tuborg, and specialty craft beers.

- Tsingtao Brewery Company Limited: Based in China, Tsingtao Brewery is one of the country’s oldest and largest breweries, known for its flagship Tsingtao beer and strong export presence worldwide.

- Asahi Group Holdings, Ltd.: A Japanese multinational beverage company, Asahi produces a wide range of alcoholic and non-alcoholic beverages, with notable brands including Asahi Super Dry and Peroni Nastro Azzurro.

- Molson Coors Beverage Company: A North American brewing giant, Molson Coors operates iconic brands like Coors Light, Miller Lite, and Blue Moon, with significant operations in both the U.S. and Europe.

- Diageo plc: Primarily a global leader in spirits, Diageo also has a strong beer portfolio including Guinness, Harp, and Smithwick’s, leveraging its distribution networks across more than 180 countries.

- Boston Beer Company, Inc.: An American craft brewery, Boston Beer is famous for Samuel Adams beers and has expanded into hard seltzers, ciders, and other craft beverages, emphasizing innovation and quality.

- Sierra Nevada Brewing Co.: Based in California, Sierra Nevada is a pioneer in the U.S. craft beer movement, known for its Pale Ale and sustainability-focused brewing practices.

- New Belgium Brewing Company, Inc.: A U.S.-based craft brewery headquartered in Colorado, New Belgium is recognized for Fat Tire Amber Ale and environmentally sustainable brewing operations.

- Stone Brewing Co.: California’s Stone Brewing is known for its bold-flavored craft beers, such as Arrogant Bastard Ale, and a strong focus on independent craft brewing and sustainability.

- Deschutes Brewery: An Oregon-based craft brewery, Deschutes is famous for Black Butte Porter and Bend-based operations emphasizing innovation, quality, and environmental stewardship.

- Lagunitas Brewing Company: Founded in California, Lagunitas produces popular craft beers such as IPA and Little Sumpin’ Sumpin’ Ale, with a strong following for bold, hoppy flavors.

- Firestone Walker Brewing Company: A California craft brewery known for innovative beers like Union Jack IPA and BarrelWorks series, combining traditional brewing techniques with experimental flavors.

- SABMiller plc: Before its acquisition by AB InBev in 2016, SABMiller was a leading multinational brewer with a strong presence in emerging markets, producing brands like Pilsner and Castle Lager.

Segments Covered in the Report

By Raw Material Type

- Malt

- Hops

- Yeast

- Water

By Processing Method

- Brewing

- Fermentation

- Maturation

- Filtration

- Packaging

By Type

- Lager

- Ale

- Stout

- Porter

- IPA

By Packaging Format

- Kegs

- Cans

- Bottles

- Draught

By Region

North America

- U.S.

- Canada

Asia Pacific

- China

- Japan

- India

- South Korea

- Thailand

Europe

- Germany

- UK

- France

- Italy

- Spain

- Sweden

- Denmark

- Norway

Latin America

- Brazil

- Mexico

- Argentina

Middle East and Africa (MEA)

- South Africa

- UAE

- Saudi Arabia

- Kuwait

Thank you for exploring our insights. For more targeted information, customized chapter-wise sections and region-specific editions such as North America, Europe, or Asia Pacific—are also available upon request.

For Detailed Pricing and Tailored Market Report Options, Click Here: https://www.towardsfnb.com/checkout/5948

Feel Free to Get in Touch with Us for Orders or Any Questions at: sales@towardsfnb.com

Unlock expert insights, custom research, and premium support with the Towards FnB Annual Membership. For USD 495/month (billed annually), get full access to exclusive F&B market data and personalized guidance. It’s your strategic edge in the food and beverage industry: https://www.towardsfnb.com/get-an-annual-membership

About Us

Towards FnB is a global consulting firm specializing in the food and beverage industry, providing innovative solutions and expert guidance to elevate businesses. With an in-depth understanding of the dynamic F&B sector, we deliver customized market analysis and strategic insights. Our team of seasoned professionals is committed to empowering clients with the knowledge needed to make informed decisions, ensuring they stay ahead of market trends. Partner with us as we redefine success in the rapidly evolving food and beverage landscape, and together, we’ll navigate this transformative journey.

Web: https://www.towardsfnb.com/

Our Trusted Data Partners

Precedence Research | Statifacts | Towards Packaging | Towards Chemical and Materials| Nova One Advisor | Food Beverage Strategies | FnB Market Pulse | Nutraceuticals Func Foods | Onco Quant | Sustainability Quant | Specialty Chemicals Analytics

For Latest Update Follow Us:

Discover More Market Trends and Insights from Towards FnB:

➡️Salt Market: https://www.towardsfnb.com/insights/salt-market

➡️Protein Bar Market: https://www.towardsfnb.com/insights/protein-bar-market

➡️Gluten-Free Bakery Market: https://www.towardsfnb.com/insights/gluten-free-bakery-market

➡️Canned Food Market: https://www.towardsfnb.com/insights/canned-food-market

➡️Dry Fruit Market: https://www.towardsfnb.com/insights/dry-fruit-market

➡️Frozen Meat Market: https://www.towardsfnb.com/insights/frozen-meat-market

➡️Fish Oil Market: https://www.towardsfnb.com/insights/fish-oil-market

➡️Soft Drink Concentrates Market: https://www.towardsfnb.com/insights/soft-drink-concentrates-market

➡️Coffee Beans Market: https://www.towardsfnb.com/insights/coffee-beans-market

➡️Soybean Market: https://www.towardsfnb.com/insights/soybean-market

➡️Beef Market: https://www.towardsfnb.com/insights/beef-market

➡️Cheese Market: https://www.towardsfnb.com/insights/cheese-market

➡️Food Packaging Market: https://www.towardsfnb.com/insights/food-packaging-market