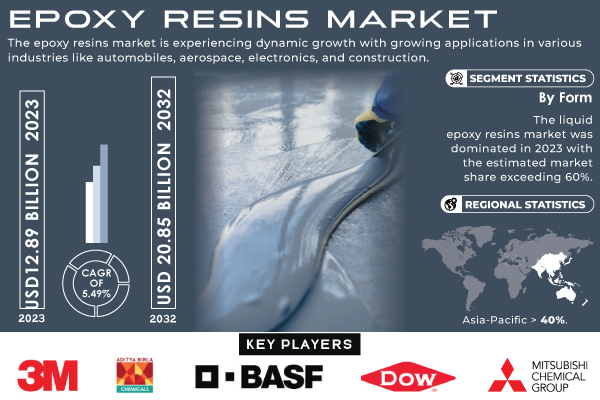

Austin, Sept. 30, 2024 (GLOBE NEWSWIRE) -- According to SNS Insider, The Epoxy Resins Market Size was valued at USD 12.89 billion in 2023 and is expected to reach USD 20.85 billion by 2032 and grow at a CAGR of 5.49% over the forecast period 2024-2032.

The epoxy resin market has gained considerable momentum from diversified applications and technological innovation. Epoxy resins have been in broad demand from industries like automotive to aerospace, where the materials' excellent mechanical properties and resistance to degradation caused by environmental factors are desired. Some recent developments, for instance, include flame-resistant epoxy resins, and the manufacturing of eco-friendly epoxy resin from orange peels-a testament to the direction in which the market is likely to take toward performance and eco-friendliness. Epoxy resins are an essential link in the automotive industry, contributing to improving durability and ensuring the safety of components, which, in turn, demonstrates better performance and longer vehicle life. An excellent example of innovative applications of epoxy resins is in automotive coatings, greatly protecting vehicles from harsh weather conditions and chemical exposure. This trend is further reinforced by companies like DIC Global, which have recently announced the development of high-performance epoxy resins with high flame resistance and less waste, underlining the commitment to sustainability.

Request Sample Report of Epoxy Resins Market 2024 @ https://www.snsinsider.com/sample-request/1461

Key Players:

- 3M (Scotch-Weld Epoxy Adhesive DP100, 3M Epoxy Adhesive 2216)

- Aditya Birla Chemicals (Epoxy Resin A, Epoxy Resin B)

- BASF SE (Epoxy Resin EPOTEC, Epoxy Hardener)

- Dow Chemical Company (D.E.R. Epoxy Resins, D.E.H. Hardener)

- DIC Corporation (DIC Epoxy Resin, DIC Epoxy Hardener)

- Huntsman Corporation (Araldite 2011, Araldite 2020)

- Kukdo Chemical Co., Ltd. (Kukdo Epoxy Resin KD-101, Kukdo Epoxy Resin KD-200)

- Macro Polymers (Epoxy Resin P-235, Epoxy Resin P-300)

- Mitsubishi Chemical Group Corporation (EPICOAT, EPICURE)

- Nan Ya Plastics Corporation (YDF Epoxy Resin, YDE Epoxy Resin)

- Olin Corporation (Epon Epoxy Resins, Epi-Cure Hardeners)

- Sinopec Corporation (Sinopec Epoxy Resin, Sinopec Epoxy Hardener)

- Westlake Epoxy (Westlake Epoxy 1000, Westlake Epoxy 2000)

- Hexion Inc. (EPON Resin, EPICURE Hardener)

- Cytec Solvay Group (AEROSIL Epoxy, EPI-REZ Resin)

- Shin-Etsu Chemical Co., Ltd. (KEP-1000, KEP-2000)

- Eternal Chemical Co., Ltd. (Eternal Epoxy Resin, Eternal Hardener)

- Sika AG (SikaForce, Sikadur)

- Scott Bader Company Ltd. (Crestafill, Crystic)

- Momentive Performance Materials Inc. (EPON Resin, SilCool Epoxy)

Furthermore, epoxy resins have been used in the aerospace industry because of their lightweight and high-strength characteristics which are very important in aircraft for superior performance and fuel economy. In the recent anti-dumping complaint filed by Olin Corporation against four countries within the European Union, there is a competitive dynamic within the industry that continues with efforts to keep the trade practices fair with emerging global demand. Recent development in epoxy resin focuses more on sustainable high-performance materials. For instance, deriving epoxy resin from orange peels is one of the most radical leaps toward reducing environmental damage from resin production to date in line with the global sustainability objectives. In addition, new formulations, which further improve flame resistance while at the same time minimizing waste, reflect an industrial response to both safety and ecological concerns.

Epoxy Resins Market Report Scope:

| Report Attributes | Details |

| Market Size in 2023 | US$ 12.89 Billion |

| Market Size by 2032 | US$ 20.85 Billion |

| CAGR | CAGR of 5.49% From 2024 to 2032 |

| Base Year | 2023 |

| Forecast Period | 2024-2032 |

| Historical Data | 2020-2022 |

| Report Scope & Coverage | Market Size, Segments Analysis, Competitive Landscape, Regional Analysis, DROC & SWOT Analysis, Forecast Outlook |

| Key Segments | •By Form (Liquid, Solid, Solution) •By Raw Materials (DGBEA, Novolac, Aliphatic, Glycidyl, Amine, Others) •By Application (Paints & Coatings, Composites, Adhesives & Sealants, Others) •By End-User (Building & Construction, Automotive, General Industrial, Consumer Goods, Wind Energy, Aerospace/Aircraft, Marine, Others) |

| Regional Analysis/Coverage | North America (US, Canada, Mexico), Europe (Eastern Europe [Poland, Romania, Hungary, Turkey, Rest of Eastern Europe] Western Europe] Germany, France, UK, Italy, Spain, Netherlands, Switzerland, Austria, Rest of Western Europe]), Asia Pacific (China, India, Japan, South Korea, Vietnam, Singapore, Australia, Rest of Asia Pacific), Middle East & Africa (Middle East [UAE, Egypt, Saudi Arabia, Qatar, Rest of Middle East], Africa [Nigeria, South Africa, Rest of Africa], Latin America (Brazil, Argentina, Colombia, Rest of Latin America) |

| Key Drivers | •Growing demand for high-performance materials in industries like automotive and aerospace is boosting the epoxy resins market • Increasing adoption of eco-friendly and sustainable materials is driving innovation and development in epoxy resin formulations |

If You Need Any Customization on Epoxy Resins Market Report, Enquire Now @ https://www.snsinsider.com/enquiry/1461

Segment Analysis

The paints & coatings segment dominated the Epoxy resin market in 2023 and accounted for over 34% of the market share. Epoxy resin-based coatings excel as protective layers across industries due to their formidable barrier against corrosion, abrasion, chemical attack, and weathering. Therefore, in applications involving the protection of metal substrates, such as steel structures, pipelines, storage tanks, and bridges, they can extend their lifespan and prevent degradation. Besides industrial uses, it also finds its way into the finishing of consumer goods for enhancement in the sphere of appearance and protection. The ability of epoxy to develop into a shiny, smooth, highly resistant surface makes it appealing for a wide variety of uses, from flooring and furniture to countertops and even decorative items.

Advancements in Epoxy Resins: Enhancing Corrosion Resistance and Sustainability Across Industries

The high-quality epoxy resin has been the foremost solution for corrosion-resistant applications due to its high durability and protection in various industries. Advanced resins have been designed for extreme environmental conditions and aggressive contact with chemicals in certain uses, such as marine, automotive, and industrial. These resins have been so developed with various sophisticated formulation techniques as to possess ideal adhesion, flexibility, and resistance to environmental factors such as moisture, UV radiation, and large amplitudes of temperature. The most recent developments in epoxy resin technology have therefore resulted in the formulation of variants that, in addition to superior corrosion protection, contribute toward sustainability goals. Innovations in resin chemistry have created products that not only minimize dependence on harmful solvents but also encourage renewable materials. High-quality epoxy resins are now at the heart of many protective coatings strategies of industries bent on longevity for their assets and decreased maintenance costs. These resins are in high demand; their efficiency in elongating the durability of infrastructure and equipment has been proven, hence increasing overall operational efficiency and safety.

Recent Developments

September 2024: DIC Corporation receives the ISCC Plus certification for its epoxy resins as a factor of sustainability.

March 2024: Nanopoxy and Nione introduce the development of nanostructured epoxy resin with new superior characteristics that give way to more advanced uses.

April 2024: A trade case has been filed against the imports of epoxy resins originating from China, India, South Korea, Taiwan, and Thailand based on various unfair trade practices.

Buy Full Research Report on Epoxy Resins Market 2024-2032 @ https://www.snsinsider.com/checkout/1461

Regional Analysis

The Asia-Pacific dominated the epoxy resins market in 2023, accounting for an estimated market share of around 40%. Due to the very rapid industrialization of various countries in the region, particularly China and India, whose economies are growing at very rapid rates, major factors for growth include an increase in the automotive and construction sectors. For instance, infrastructural development and a thriving automotive sector in China have spurred high demand for epoxy resins used in coatings, adhesives, and composites. Besides, the growing manufacturing base in India with increasing investments in a number of infrastructure projects is further strengthening the position of the region. These factors put together have consolidated the position of the Asia-Pacific region in the global epoxy resins market.

Key Takeaways:

- The epoxy resin market is hugely driven by improved material performance and sustainability.

- Recent innovations also include the development of bio-friendly resins of natural origin and value-added formulations to minimize waste and ensure safety.

- Rapid industrialization and increasing demand from both the automotive and construction sectors make the Asia-Pacific region the leading market.

- The competitive nature of dynamics and attempts at rebalancing in the market has been underlined by ongoing developments and regulatory events, such as anti-dumping complaints.

Table of Contents – Major Key Points

1. Introduction

1.1 Market Definition

1.2 Scope (Inclusion and Exclusions)

1.3 Research Assumptions

2. Executive Summary

2.1 Market Overview

2.2 Regional Synopsis

2.3 Competitive Summary

3. Research Methodology

3.1 Top-Down Approach

3.2 Bottom-up Approach

3.3. Data Validation

3.4 Primary Interviews

4. Market Dynamics Impact Analysis

4.1 Market Driving Factors Analysis

4.1.1 Drivers

4.1.2 Restraints

4.1.3 Opportunities

4.1.4 Challenges

4.2 PESTLE Analysis

4.3 Porter’s Five Forces Model

5. Statistical Insights and Trends Reporting

5.1 Production Capacity and Utilization, by Country, by Type, 2023

5.2 Feedstock Prices, by Country, by Type, 2023

5.3 Regulatory Impact, by Country, by Type, 2023.

5.4 Environmental Metrics: Emissions Data, Waste Management Practices, and Sustainability Initiatives, by Region

5.5 Innovation and R&D, by Type, 2023

6. Competitive Landscape

7. Epoxy Resins Market Segmentation, by Form

8. Epoxy Resins Market Segmentation, by Raw Materials

9. Epoxy Resins Market Segmentation, by Application

10. Epoxy Resins Market Segmentation, by End-User

11. Regional Analysis

12. Company Profiles

13. Use Cases and Best Practices

14. Conclusion

Access Complete Report Description of Epoxy Resins Market Report 2024-2032 @ https://www.snsinsider.com/reports/epoxy-resins-market-1461

[For more information or need any customization research mail us at info@snsinsider.com]

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

SNS Insider Offering/ Consulting Services:

Go To Market Assessment Service

Total Addressable Market (TAM) Assessment

Competitive Benchmarking and Market Share Gain